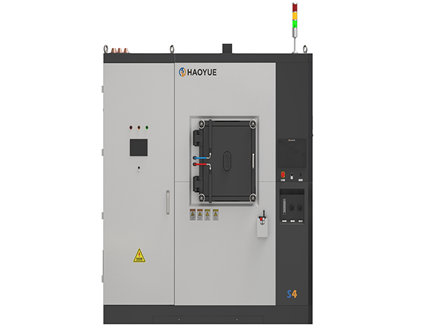

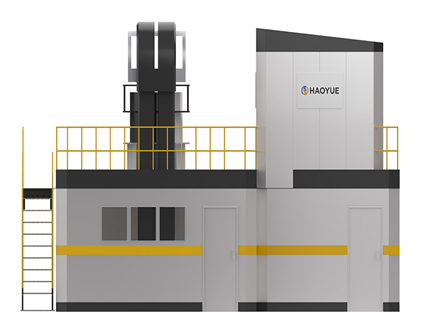

1600℃ Vertical Tube Furnace

Tube furnace is a new type of electric furnace with high performance and high energy saving developed by adopting international advanced technology. There are many kinds of tube furnace types, such as single tube, double tube, horizontal, openable, vertical, single temperature zone, double temperature zone and three temperature zone. It is mainly used in experiments and small batch production in colleges, scientific research institutes, industrial and mining enterprises. The utility model has the advantages of safety and reliability, simple operation, high temperature control precision, good heat preservation effect, wide temperature range, high uniformity of furnace temperature, multiple temperature zones, optional atmosphere and vacuum furnace type。

Technical Data

Technical Features

1 The furnace material is imported ceramic fiber, which has the advantages of balanced temperature field, low surface temperature, fast heating rate and energy saving;

2 High quality silicon carbon rod or silicon molybdenum rod is adopted for electric heating element, with high surface load and fast heating speed;

3 Stainless steel sealing flange with hinge structure is adopted at both ends of furnace body, which is convenient for operation, high temperature resistance and corrosion resistance;

4 High purity corundum tube is used as protective tube;

5 The length of the heating zone is 600 mm, and the temperature field is more uniform;

6 The vacuum degree of furnace can reach 10-3 PA with diffusion pump or molecular pump;

7 The furnace body adopts double-layer air insulation technology, equipped with automatic cooling fan to reduce the temperature of furnace shell;

8 Four universal wheels are installed on the furnace body to facilitate the overall movement;

9 The standard control system adopts domestic 30 segment program to control temperature, with temperature control accuracy of ± 1 ℃, phase-shifting trigger and silicon controlled rectifier control;

Precautions: when heating the sample and injecting protective gas, it is necessary to ensure that the inlet and outlet valves are opened at the same time to prevent the furnace tube from cracking due to excessive pressure in the protection tube;

Specifications

| No | Temp zone | Type | Dia*tube size(mm) | heating zone(mm) | flat-temperature zone(mm) | Outer dia(mm) | Max temp(℃) | Working temp(℃) | Power(kw) | Voltage(V) |

| B1 | Single | HTF1600-8/30-VT | φ80*1000 | 300 | 120 | φ80 | 1600 | 1500 | 7 | 220 |

| B1 | Single | HTF1600-10/30-VT | Φ100*1000 | 300 | 120 | Φ100 | 1600 | 1500 | 7 | 220 |

Application

The low temperature series tubular furnace system is operated periodically for enterprises, colleges and research institutions.

The equipment provides users with vacuum, controllable atmosphere and high temperature experimental environment, which is applied in semiconductor, nanotechnology, carbon fiber and other new materials and processes.

Tubular atmosphere furnace is mainly used for sintering, coating, heat treatment and ash determination of graphite, ceramics, lithium batteries, rare metals, rare earth and biological materials under the protection of atmosphere. It is also suitable for the preparation of graphene, carbon nanotubes, molybdenum disulfide and other two-dimensional materials.