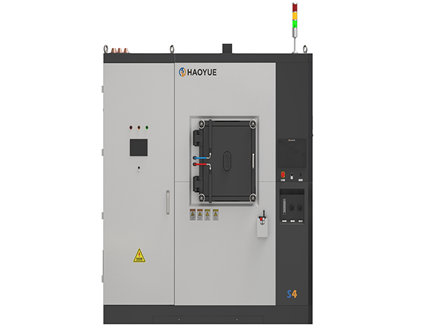

P series Hot pressing Laboratory Vacuum furnace

A vacuum hot pressing furnace is a complete set of equipment that forms materials by hot pressing under vacuum (or other atmosphere) conditions. It mainly uses resistance or induction heating, and is pressurized up and down by a pressure head driven by an oil cylinder. At high temperatures, the solid particles of the raw material are bonded together, the grains grow, the voids (pores) and grain boundaries gradually decrease, and through material transfer, their total volume shrinks, the density increases, and finally becomes a dense polycrystalline sintered body with a certain microstructure, thereby pressing the material into shape.

Technical Data

Adopting a horizontal and side door opening structure: high precision in loading and unloading molds.

Fast temperature rise and fall: the induction heating rate is 100 ℃ per minute (less than or equal to 1600 ℃), and the resistance rate is 20 ℃ per minute (greater than 1600 ℃);

Good temperature uniformity: The average temperature uniformity is plus or minus 5 ℃ (measured at five points, with a constant temperature zone of 1000 ℃ for one hour before testing);

High pressure accuracy: Using a hydraulic control system, the pressure accuracy is 0.3%.

Adopting single temperature zone control: reserving two temperature measurement holes for high-temperature detection.

Good safety performance: Adopting HMI+PLC+PID pressure sensor control, safe and reliable;

Good sealing performance: The dynamic pressure heads are sealed with corrugated pipes to ensure no air leakage.

Specifications

Tech specifications / Models | P2 (Standard Edition) | P2 Plus (Standard Plus) | P2 Pro (high-end version) | P2 Pro Max (high-end enlarged version) |

Diameter of metal indenter | 85mm | 125mm | 85mm | 125mm |

Diameter of graphite indenter | 85mm | 125mm | 85mm | 125mm |

Maximum product diameter | ≤Φ80 (raw material) | ≤Φ120 (raw material) | ≤Φ80 (raw material) | ≤Φ120 (raw material) |

Product height range | 10≤H≤60mm | 10≤H≤60mm | 10≤H≤60mm | 10≤H≤60mm |

Maximum pressure | 30 tons | 50 tons | 30 tons | 50 tons |

Way of Pressure | Lower pressure | Lower pressure | Lower pressure | Lower pressure |

Stroke | 100mm | 100mm | 100mm | 100mm |

Pressure head opening height | 160mm | 160mm | 160mm | 160mm |

Outline dimensions of the mold sleeve | Φ160x100mm | Φ200x100mm | Φ160x100mm | Φ200x100mm |

Product dimensions (DWH) | 1550x1425x1850mm | 1550x1425x1850mm | 1550x1425x1850mm | 1550x1425x1850mm |

P2 model

| No. | Max.Temperature (℃) | Heater | Chamber Size (mm) | External Dimentions(mm) | GW (Kg) | Pressure (kN) | Heating Power(kW) | Vacuum(Pa) | Application |

| P2GR20 | 2000 | Graphite | W200×H200×D300 | W1425×D1550×H1850 | 1500 | 300 | 45 | 6.7*10-3 | Hot-press/Sintering |

| P2GR24 | 2400 | Graphite | W200×H200×D300 | W1425×D1550×H1850 | 1500 | 300 | 50 | 6.7*10-3 | Hot-press/Sintering |

| P2CO20 | 2000 | Induction | φ200×H200 | W2025×D1550×H1850 | 1600 | 300 | 45 | 6.7*10-3 | Hot-press/Sintering |

| P2CO24 | 2400 | Induction | φ200×H200 | W2025×D1550×H1850 | 1600 | 300 | 50 | 6.7*10-3 | Hot-press/Sintering |

Application

Cemented Carbide(WC、TiC)

Performs dewaxing, degassing, and sintering in sequence

Oxide Ceramics

Performs dewaxing, degassing, and sintering processes in sequence

Application: Aluminium Oxide(Al2O3), Zirconium Oxide(ZrO2)

Non-Oxide Ceramics

Performs dewaxing, degassing, and sintering processes in sequence

Application: Silicon Carbide(SiC), Silicon Nitride(Si3N4), Aluminum Nitride (AlN)

Metals and Alloys

Performs dewaxing, degassing, and sintering in sequence

Graphite

Performs degassing and purification in sequence