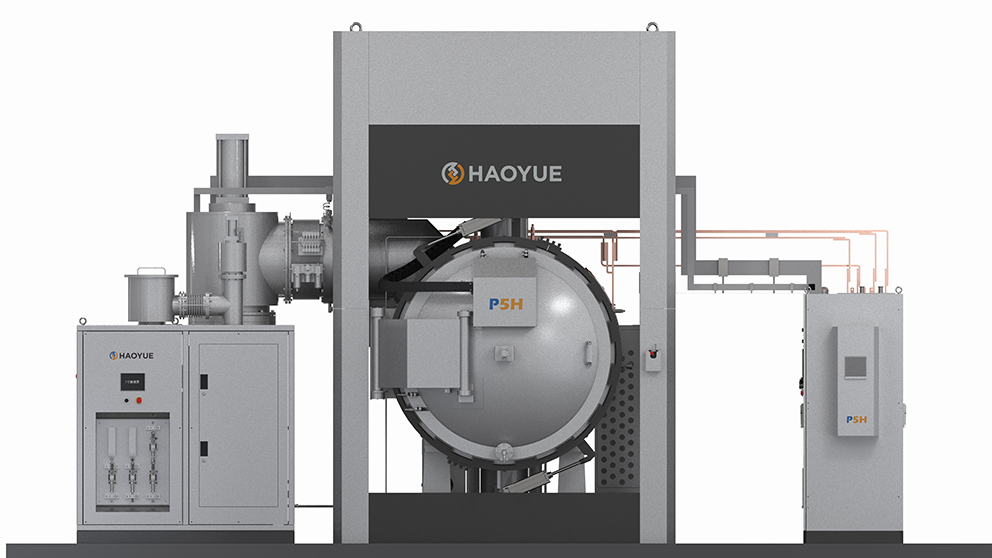

P5H Vacuum Hot-pressing Furnace(Graphite)

Good Design Optimization / Temperature Uniformity / Fast Heating Speed / High Pressure Accuracy / Good Safety Performance

A vacuum hot pressing furnace is a complete set of equipment that forms materials by hot pressing under vacuum (or other atmosphere) conditions, Mainly using induction heating, the pressure head driven by the oil cylinder pressurizes up and down. At high temperatures, the raw material. The mutual bonding of solid particles leads to grain growth, and the number of voids (pores) and grain boundaries gradually decreases. The transfer of matter results in a total volume contraction, an increase in density, and ultimately becomes a material with a certain microstructure, Dense polycrystalline sintered body, thereby compressing the material into shape.

Technical Data

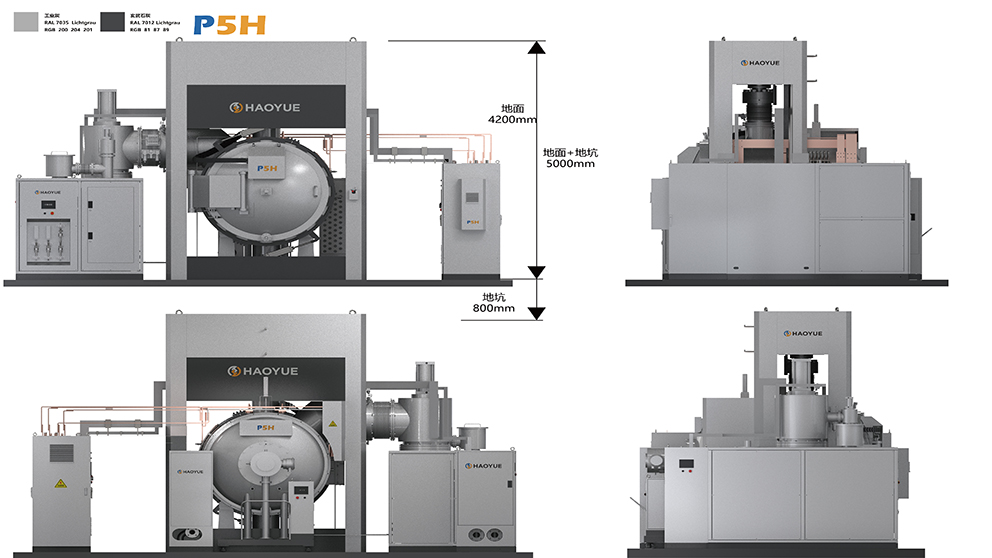

Adopting a vertical and upward opening structure: high precision for loading and unloading molds, easy to operate;

Fast heating: heating rate of 20°C/minute (<1600°C), heating rate of 10°C/minute (>1600°C); Design optimization is good: The thermal field of the pressurized chamber has been simulated and calculated under thermal conditions, with very high temperature uniformity and compatibility, The heating elements and insulation layer are designed with modular optimization;

Good temperature uniformity: The average temperature uniformity is ±5°C (measured at 5 points, with a constant temperature zone of 1000°C for 1 hour before testing);

High pressure accuracy: Using a hydraulic control system, the pressure accuracy is ±3%; Adopting multi temperature zone control: reserving multiple temperature measurement holes for high-temperature monitoring purposes;

Good safety performance: Adopting HMI+PLC+PID pressure sensing control, safe and reliable; Good sealing performance: The dynamic pressure heads are sealed with corrugated pipes to ensure no air leakage;

High degree of automation: Except for loading and unloading, all other processes are fully automated, digitized, intelligent, and do not require manual intervention.

Specifications

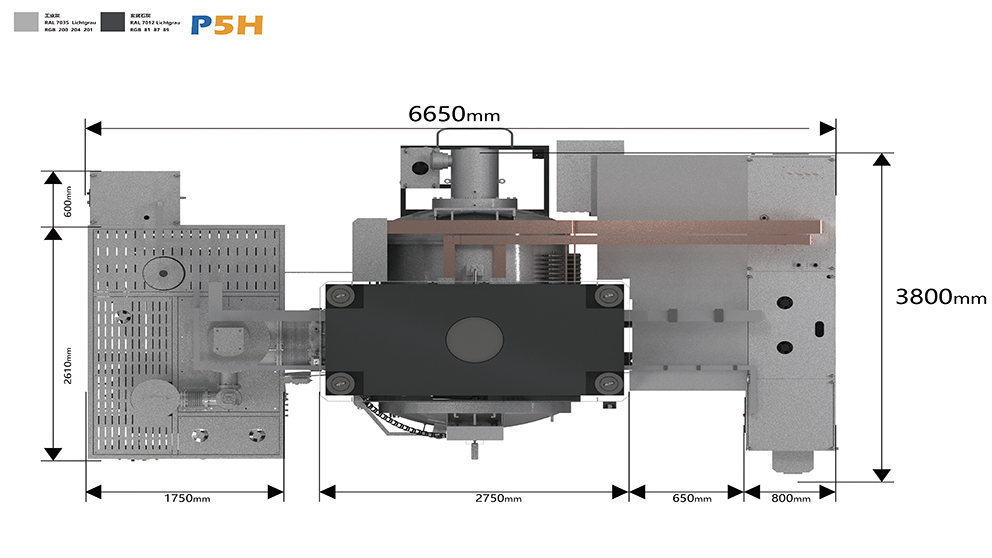

Tech Specification/Models | P5 (Standard Edition) | P5 Plus (Standard Plus) | P5 Pro (high-end version) | P5 Pro Max (high-end enlarged version) |

Diameter of metal indenter | 300mm | 360mm | 300mm | 360mm |

Diameter of graphite indenter | 300mm | 360mm | 300mm | 360mm |

Maximum product diameter | ≤Φ300 (raw material) | ≤Φ360 (raw material) | ≤Φ300 (raw material) | ≤Φ360 (raw material) |

Product height range | 10≤H≤100mm | 10≤H≤100mm | 10≤H≤100mm | 10≤H≤100mm |

Maximum pressure | 300 tons | 400 tons | 300 tons | 400 tons |

Way of Pressure | Apply pressure upwards | Apply pressure upwards | Apply pressure upwards | Apply pressure upwards |

Stroke | 200mm | 200mm | 200mm | 200mm |

Pressure head opening height | 500mm | 500mm | 500mm | 500mm |

Outline dimensions of the mold sleeve | Φ500x300mm | Φ520x300mm | Φ500x300mm | Φ520x300mm |

Product dimensions (DWH) |

| No. | Chamber Size (mm) | Sample Dia.(mm) | Pressure (KN) | Stroke(mm) | Ultimate Vacuum(Pa) | Operation Temperature (℃) | Max. Dia. of Mold (mm) |

| P5VGR22 | φ500*H700 | ≤300 | ≤3000 | 400 | 5 | 2200 | ≤500 |

| P5HGR22 | φ500*H500 | ≤300 | ≤3000 | 200 | 5.0*10-3 | 2200 | ≤500 |

| P7VGR22 | φ700*H900 | ≤420 | ≤6000 | 400 | 5 | 2200 | ≤700 |

| P7HGR22 | φ700*H600 | ≤420 | ≤6000 | 200 | 5.0*10-3 | 2200 | ≤700 |

Application

Suitable for ceramic materials such as niobium oxide, silicon carbide, boron carbide, boron nitride, or graphene carbon, High temperature pressure sintering and densification powder metallurgy of fiber and high-temperature alloy metal powder materials,High temperature hot forming of new materials such as gold and functional ceramics can also be used for powder or compact at low temperatures, Heat treatment at the melting point of the main components, with the aim of achieving metallurgical properties between particles combine to enhance its strength.

For example: brake discs made of iron and copper based powder materials for aircraft landing, bulletproof vests, armored vehicle protective plates, and

straight upgrade aircraft's bulletproof armor, etc.