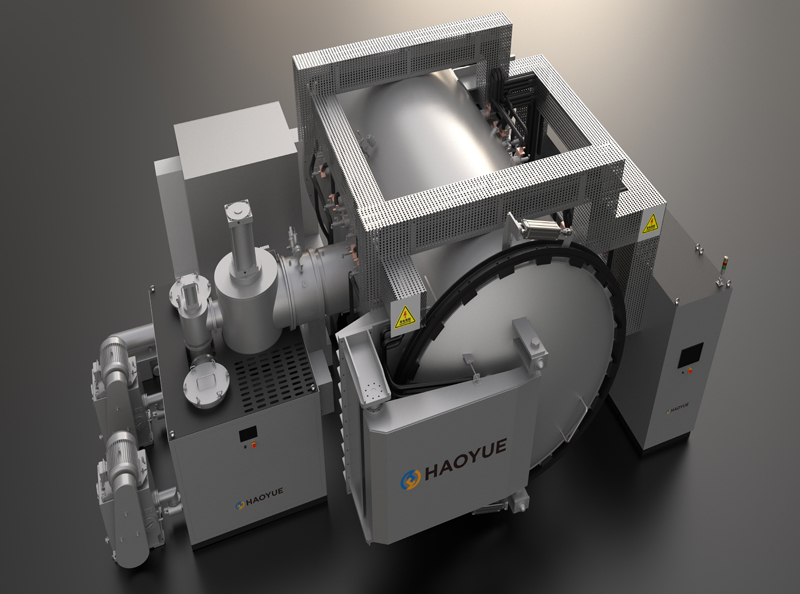

Proper Price 1600℃ Muffle Furnace

Box type resistance furnace is a common form of electric furnace, which can be divided into vertical, horizontal, split and integrated. The temperature range is divided into below 1200 ℃, 1400 ℃, 1600 ℃, 1700 ℃, 1800 ℃, etc. the resistance wire, silicon carbon rod and silicon molybdenum rod are used as heating elements respectively. The box type electric furnace can be selected according to the needs. In addition to the usual heating in the air, the box type electric furnace also has the air ventilation and sealed vacuum extraction furnace, with various forms. Widely used in ceramics, metallurgy, electronics, glass, chemical industry, machinery, refractory, new material development, special materials, building materials and other fields of production and experiment.

Technical Data

Muffle Furnace Technical Features

1 The double shell structure is adopted, the inner layer is stainless steel structure, and the shell is carbon steel.

2 The furnace material is made of alumina polycrystalline fiber, which can save 50% energy and even temperature field.

3 High quality alloy resistance wire is used as heating element. The resistance wire is located at the left and right and bottom position to ensure high temperature uniformity and the best temperature field effect.

4 K-type thermocouple is used to measure the temperature, which is located directly behind the furnace, and the temperature measurement is accurate.

5 The air cooling system is equipped between the double-layer furnace shells, which can make the surface temperature of the furnace body quickly drop, and the surface temperature of the furnace shell is less than 60 ℃.

6 The automatic power-off function of furnace door opening enables automatic power-off after the furnace door is opened.

7 Overtemperature protection function, when the temperature exceeds the allowable setting value, it will automatically cut off power and give an alarm.

8 Leakage protection function, when the furnace body leakage, automatic power off.

Shanghai haoyue technology co., Ltd. Is muffle furnace manufacturer a high-tech enterprise integrating r & d, production and sales of electric furnace. our company is located in shanghai, the center of china's economy and technology. It has large-scale modern standard plant, complete set of processing equipment and perfect quality inspection system. It has gathered a number of technical elites who have been engaged in the manufacture and service of heat treatment furnace, vacuum furnace and special furnace for a long time. Our muffle furnace qualification certification.

Specifications

| No | Type | Capacity(L) | working zone(mm)W×H×L | Loading method | Note |

| Amini | HMF1600-10/10/10 | 1 | 100×100×100 | SL | Laboratory |

| A1 | HMF1600-15/15/15 | 3 | 150×150×150 | SL | Laboratory |

| A2 | HMF1600-20/20/30 | 12 | 200×200×300 | SL | Laboratory |

| A3 | HMF1600-25/25/30 | 19 | 250×250×300 | SL | Laboratory |

| A4 | HMF1600-30/30/40 | 36 | 300×300×400 | SL | Laboratory |

| A5 | HMF1600-45/45/45 | 91 | 450×450×450 | SL | Industrial |

| A6 | HMF1600-60/60/60 | 216 | 600×600×600 | SL | Industrial |

Application

This series of resistance furnaces are used for chemical analysis, physical measurement, metal heat treatment and high temperature sintering and annealing in powder metallurgy industry.

Main Ingredients

Safety Features:

These muffle furnaces are microprocessor controlled programmable muffle furnaces that offer easy and safe operation even at high temperature. These systems are designed with your safety in mind. Multi-layered insulation keeps external surfaces (cabinet) cool to the touch. Door safety switch (optional accessory) stops power to heating elements when door is opened.

Related Products:

Durable Using 1700℃ Muffle Furnace

1800℃ Muffle Furnace for Sintering Ceramic Metal Powder Chemicals

Related News:

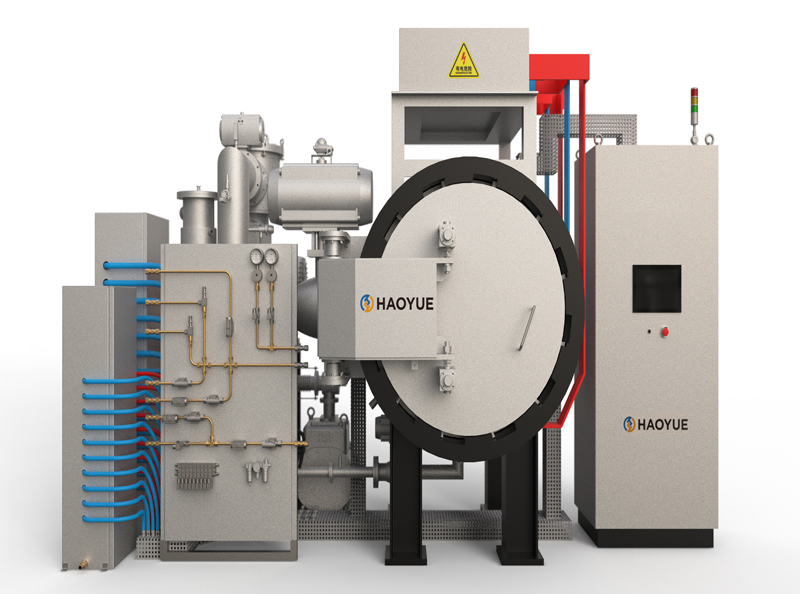

Vacuum Sintering: How to Choose the Right Sintering Atmosphere?

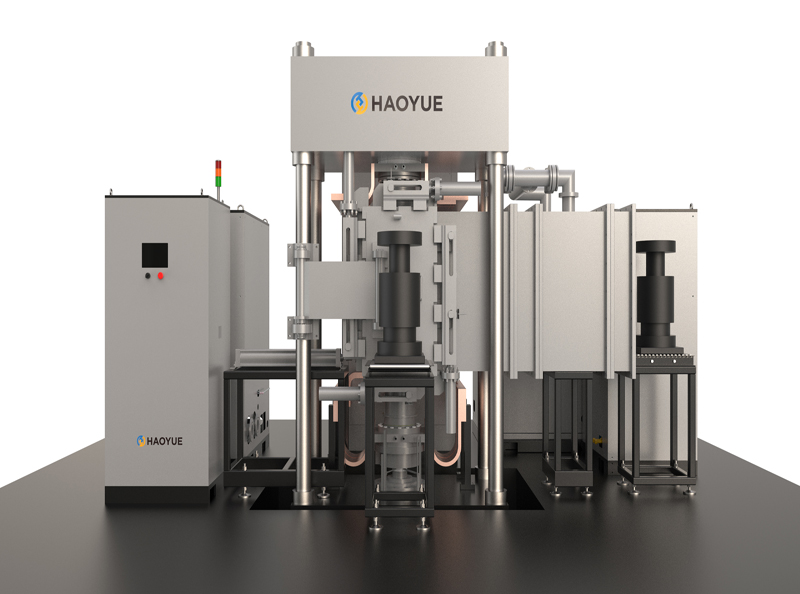

Classifications and Applications of Vacuum Hot Press Sintering Furnaces