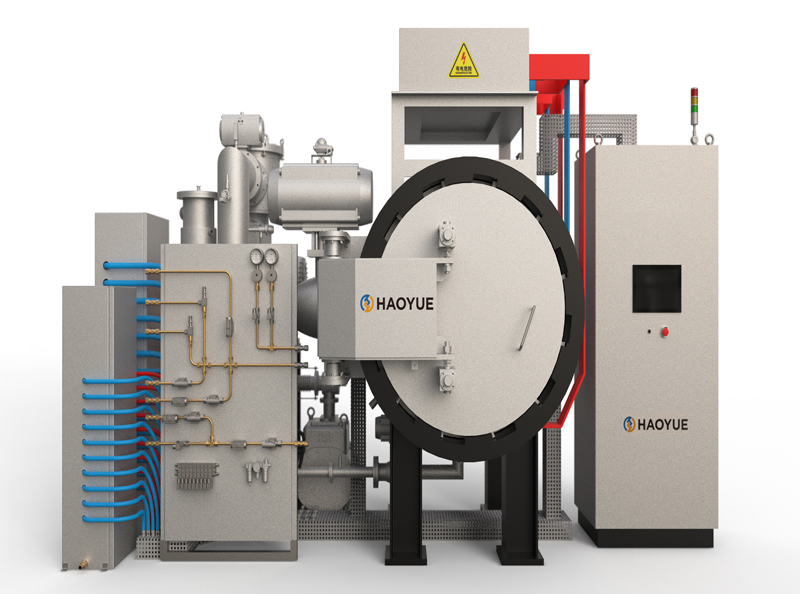

China Factory Direct Wholesale 6MPa Gas Pressure Sintering Furnace

Gas pressure sintering means that the sintering process is carried out at low pressure first, then the material is sintered under normal pressure and finally sintered at high pressure (the result is to further increase the fatigue state of the material and quickly eliminate the stress in the material), After the high temperature and high pressure sintering process, the mechanical properties (hardness, strength, toughness, etc.) of the materials are better than those of the ordinary sintering process.

Technical Data

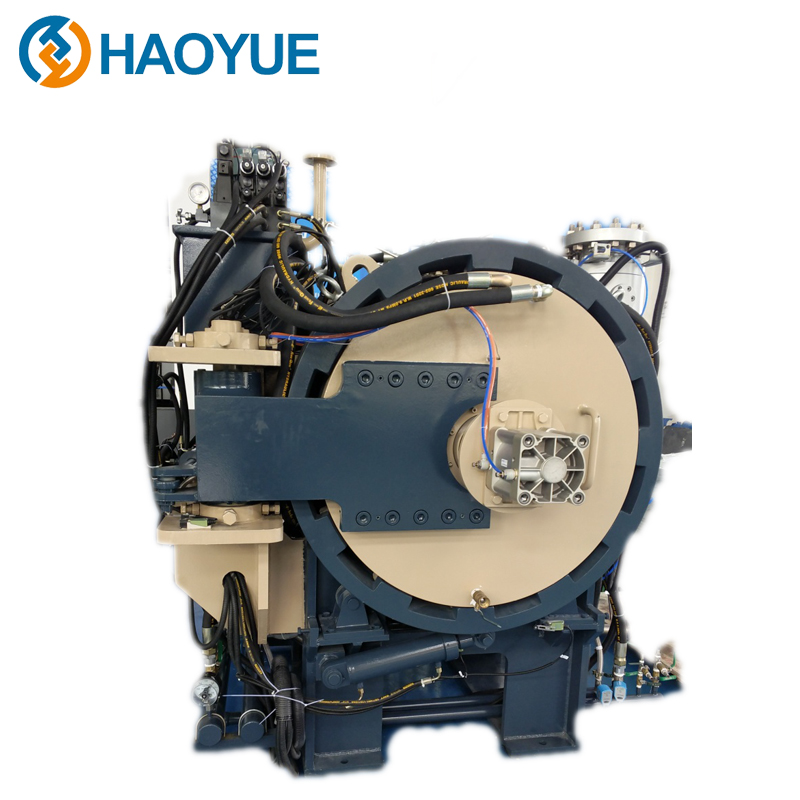

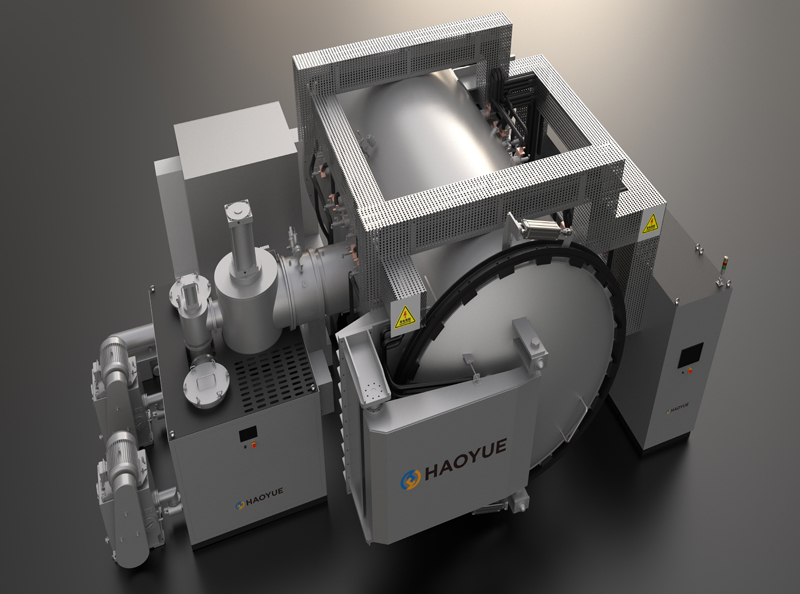

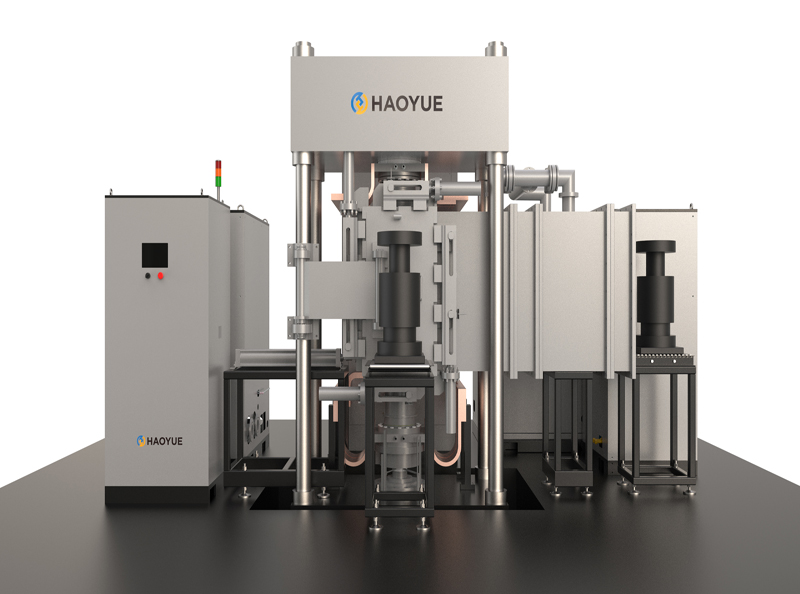

1. The equipment is designed and manufactured according to the requirements of class 3 pressure vessel standards, and 16MnR or 304 furnace shell is adopted.

2. The door lock of the furnace is a bolt or tooth meshed quick release flange, which is easy to operate, safe and reliable.

3. The furnace cover is lifted and lowered by electro-hydraulic method, which is easy to operate and reduces labor intensity.

4. The insulation material in the furnace is carbon deposition composite hard felt, and the heating element is graphite imported from Germany.

5. The temperature measuring element adopts the ultra-high temperature protective tube developed by our company, which is matched with tungsten rhenium thermocouple, and the service life of thermocouple wire is up to half a year.

6. The control system is plc+ touch screen, with complete safety interlock protection and alarm functions.

7. The high-pressure valves and pipelines are all American "Swagelok" brand or equivalent imported products, which are safe and reliable.

Specifications

6MPa Gas Pressure Sintering Furnace | |||

| Type | 3312-6 | 4412-6 | 5518-6 |

| Dimension of usable space | 300×300×1200mm | 400×400×1200mm | 500×500×1800mm |

| Max. loading weight | 500KG | 600KG | 1500KG |

| Heating power/ Total power | 300KW/340KW | 300KW/340KW | 440 KW/480KW |

| Max. designing pressure | 6MPa | ||

| Max. working pressure | 5.80MPa | ||

| Max. designing temperature | 1600℃ | ||

| Max. working temperature | 1550℃ | ||

| Temperature control | 3 zones | ||

| High temperature uniformity | ≤±5℃ | ||

| Max. heating up speed (without loading) | 15℃/min(≤1000℃);10℃/min(1000-1520℃) | ||

| Max. Vacuum | ≤ 2Pa(2.0×10-2 torr), tested in cold and clean chamber | ||

| Leak rate | ≤ 2Pa/h, tested in cold and clean chamber | ||

| Wax collecting rate | ≥98﹪(Paraffin as the binder) | ||

| Cooling(with loading)(Inlet cooling water ≤30℃, chamber pressure 50bar) | From 1450 ℃ to 100℃, 5~7h | From 1450 ℃ to 100℃, 6~8h | From 1450 ℃ to 100℃, 8~10h |

Application

Oxide Ceramics

Transparent Ceramics

Silicon Nitride

Cemented Carbide