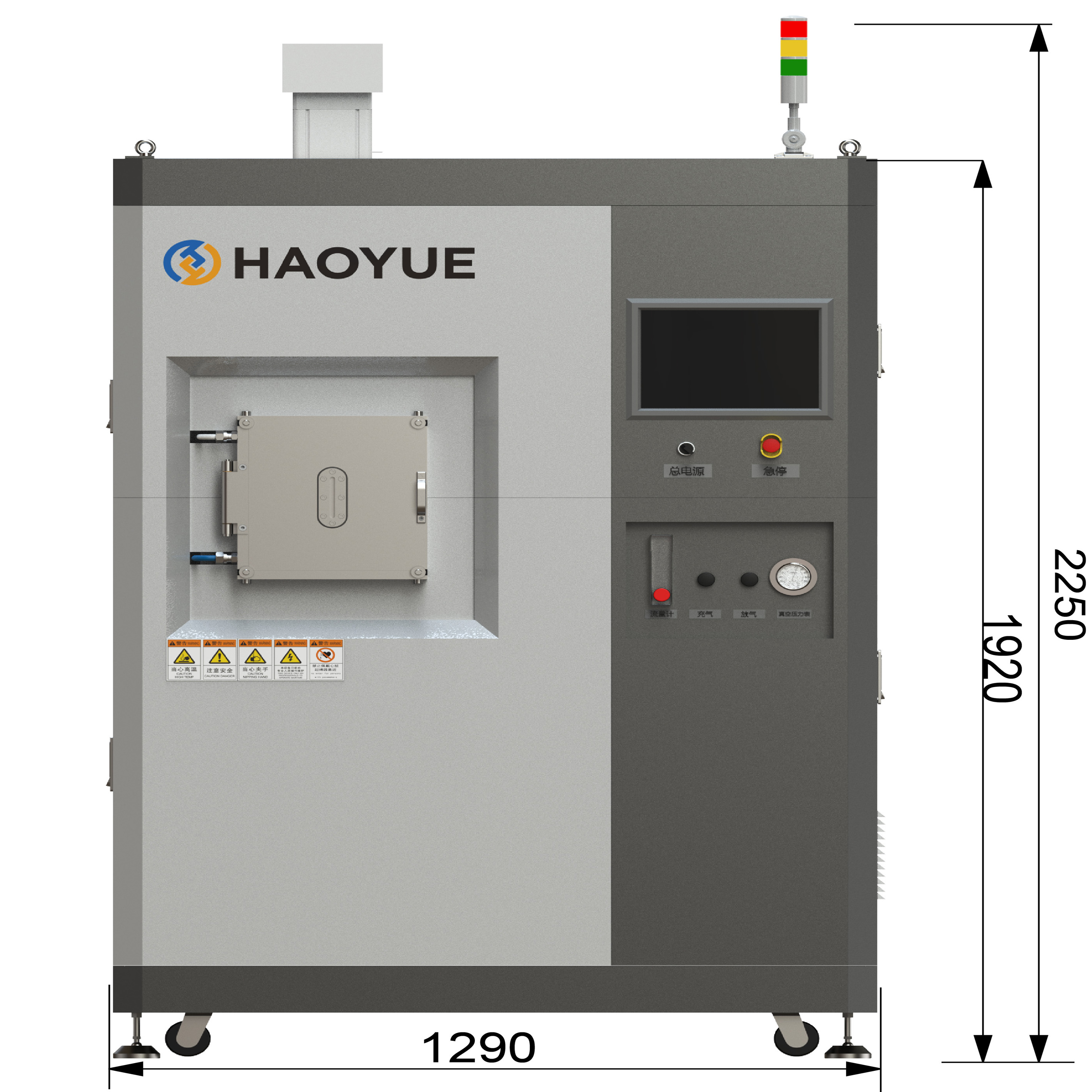

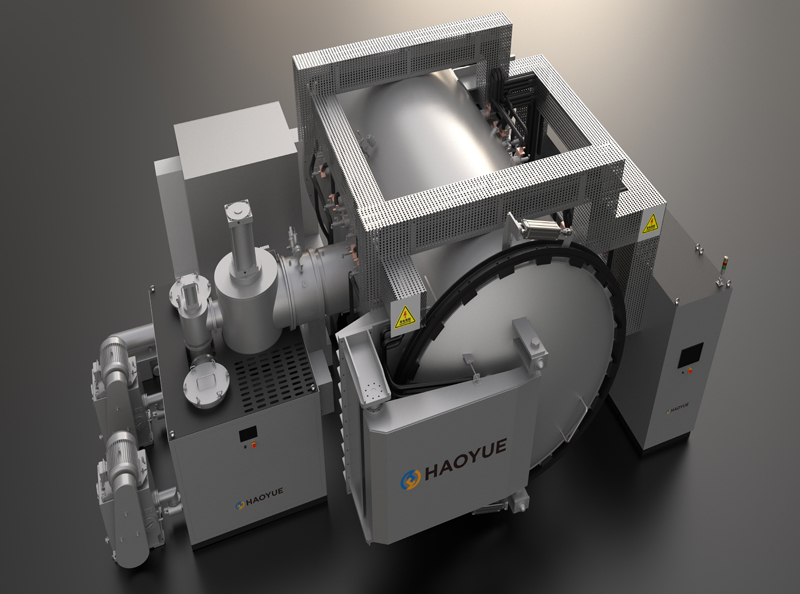

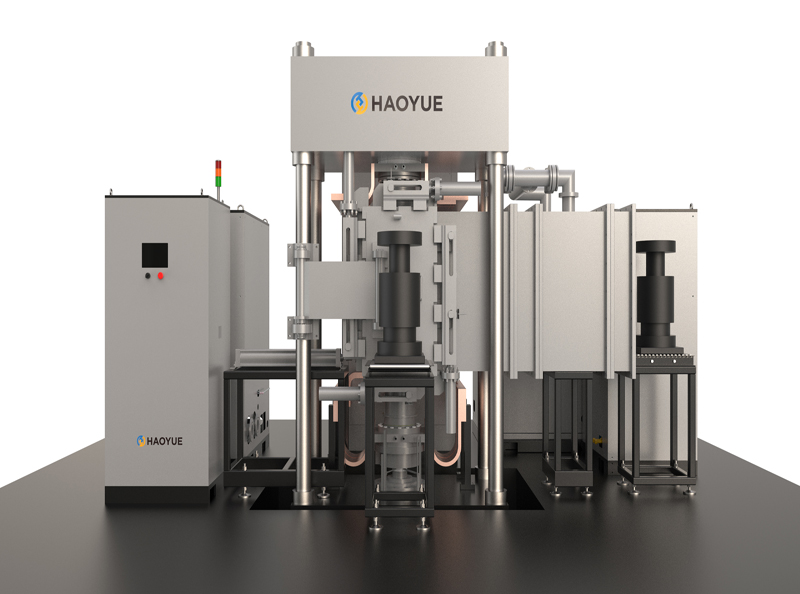

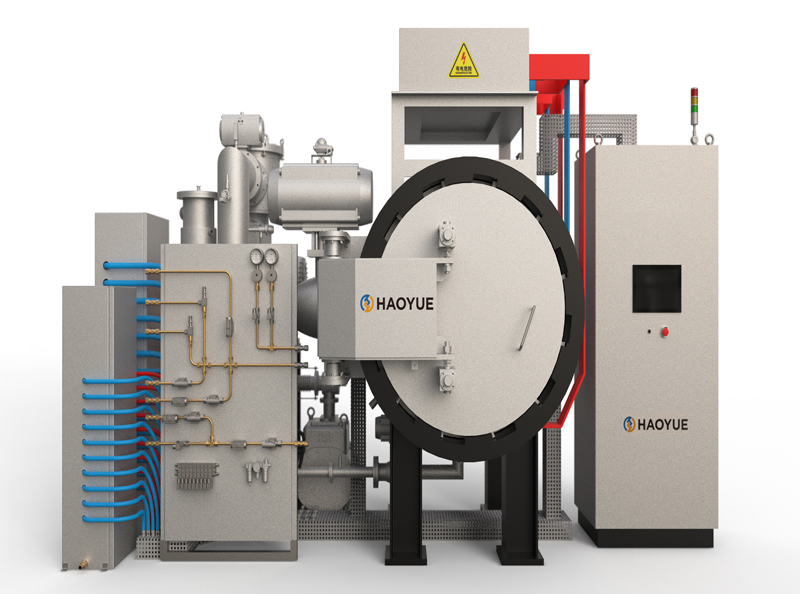

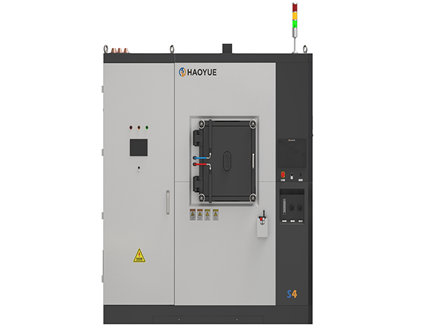

Controllable Temperature Smini Spark Plasma Sintering System

The spark plasma sintering system is one of the most advanced sintering systems in the world today. It is a new type of rapid sintering technology that applies pulse current and axial pressure between two electrodes for powder sintering densification. It has the distinctive characteristics of fast heating rate, short sintering time, controllable structure, energy saving and environmental protection. It can be used to prepare metal materials, ceramic materials, composite materials, nano block materials, amorphous block materials, gradient materials.

Technical Data

Rapid heating and cooling, greatly shortening production time and reducing production costs (heating rate can reach 100 ~ 200℃ / min).

1、Self-developed high efficiency and energy saving power supply

Adopting self-developed pulse frequency conversion DC power supply, The current output is stable and the power consumption is greatly reduced, energy saving and environmental protection.

2、Precised pressure control system

Servo valve is used to control the pressure output of the hydraulic cylinder, and the control accuracy can reach 1/1000.

Thermocouple and two-color infrared instrument are used to measure the temperature.

3、Advanced automatic control and reliable safety interlock

Adopting computer to realize automatic control of temperature and action process, PLC safety interlock. It has sound and light alarm and interlock function such as over-pressure, over-temperature and high water temperature.

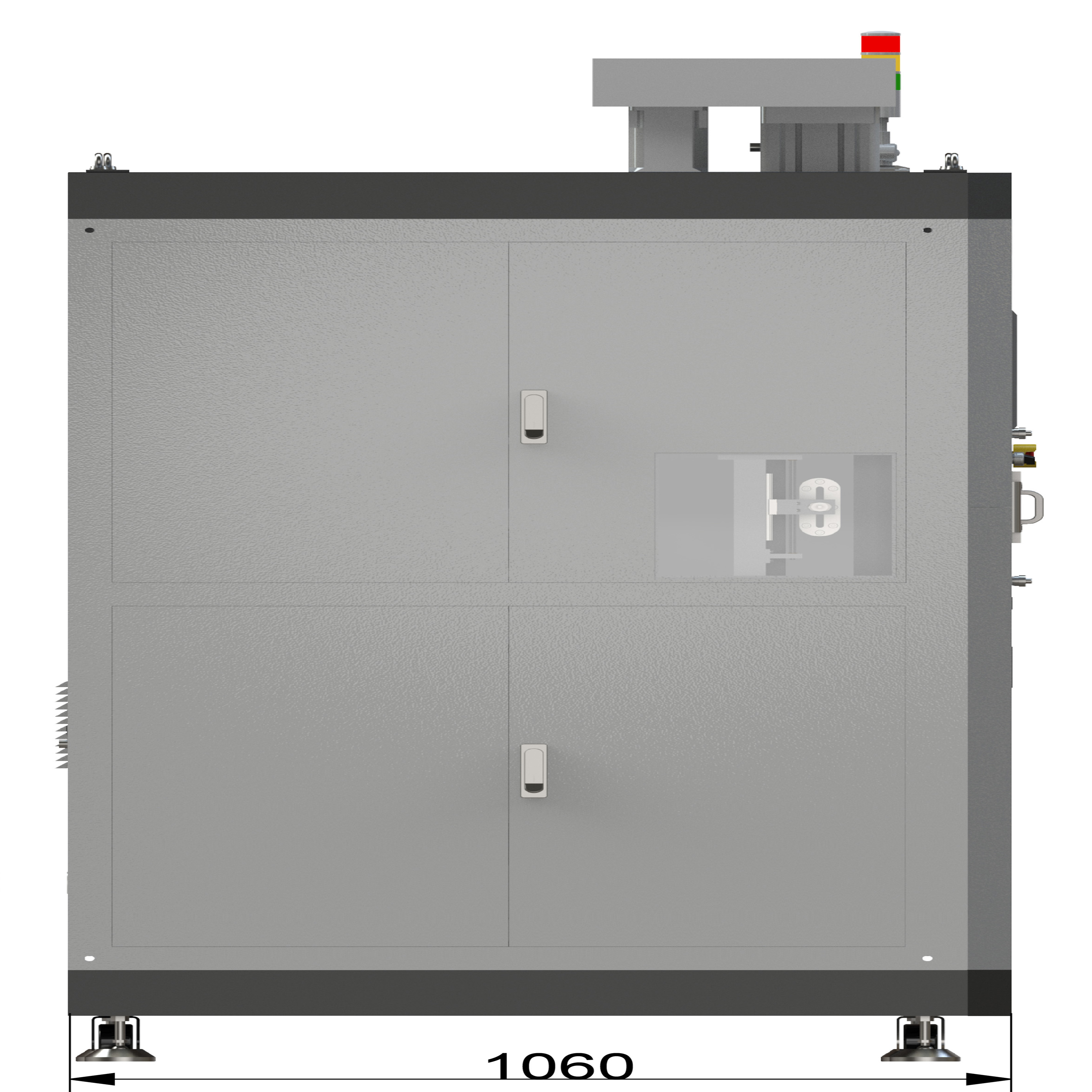

Specifications

| Smini Spark Plasma Sintering System | |

| Model | VHPsp-6/18-2400(Smini) |

| Equipment Loading Method | Horizontal side loading |

| Max.Power | 30KW |

| Output Voltage | 0 ~ 10V |

| Output Current | 0 ~ 3000A |

| Pulse Control | ON/1~255ms OFF/1~255ms |

| Max. Sintering Temp | 2400℃(The temperature will change according to the resistance of the sintered material) |

| Product Diameter | ≤φ15mm |

| Mold Diameter | ≤φ60mm |

| Open Height | 180mm |

| Z-axis stroke | 80mm |

| Displacement Accuracy | ±0.005mm |

| Max. Pressure | 29KN(3Ton) |

| Pressure Control | Servo motor |

| Pressure Accuracy | ±0.1% |

| Pressure method | Single-way pressure, bottom pressure |

| Max.Vacuum | 1Pa/8.0×10-4Pa(8.0×10-2/8.0×10-6 torr)Optional |

| Pressure Rise Rate | ≤ 2Pa/h |

| Temperature Control and Measurement | PLC program temperature control ≤1000℃ with K-type thermal couple >1000℃ with infrared thermometer |

| Gases | High-purity argon or high-purity nitrogen, inflation pressure ≤0.02MPa (adjustable) |

| Cooling Water Requirements | Water pressure 0.2 ~ 0.4MPa, 4m3/h |

Application

Sintered nanomaterial without significant grain growth

FGM (Functionally Graded Materials)

Composite materials

Innovative carbide metals

Aluminum and copper alloys as well as intermetallic compounds

Structural and functional ceramics

Electronic Materials

Sputtering target material

Bioma materials

Porous materials

Magnetic materials