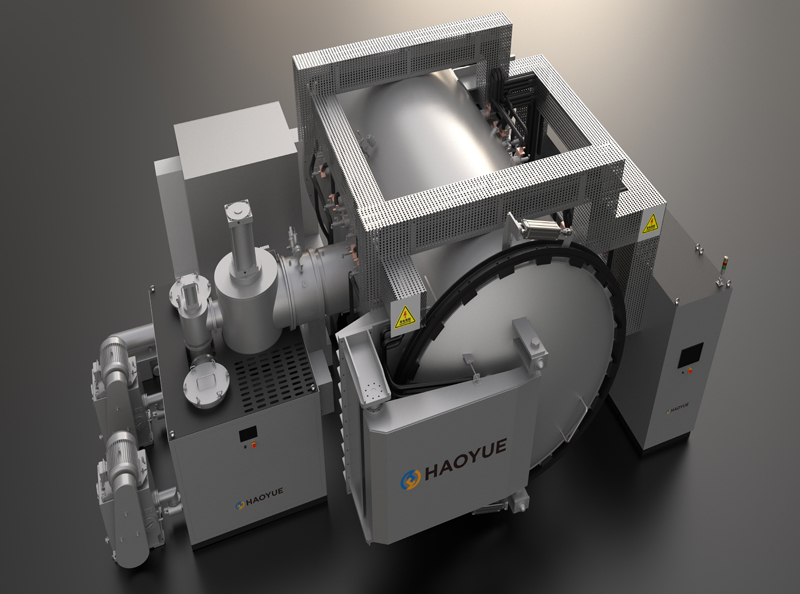

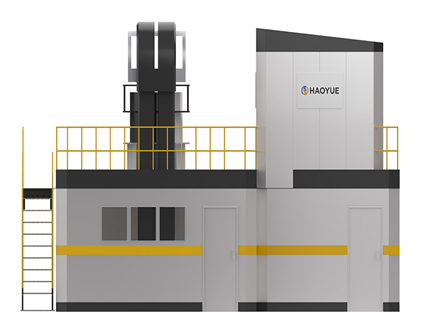

SPS Sintering System (SPS+Induction)

Fast Heating Rate / Short Sintering Time / Controllable Organizational Structure /Energy-saving and Environmental Protection

The SPS (Spark Plasma Sintering) DCS discharge plasma sintering system is one ofthe most advanced sintering systems in the world today. It isa new rapid sintering technology that applies pulse current and axial pressure between two electrodesto densify powder sintering. It has distinct characteristics such as fast heating rate, short sintering time, controllable organizational structure, energy conservation and environmental protection. It can be used to prepare metal materials, ceramic materials, composite materials, as well as nano bulk materials, amorphous bulk materials, gradient materials, etc.

Technical Data

SPS Induction Furnace Supplier: HaoYue SPS Sintering System (SPS+Induction)

The SPS Sintering System (SPS+Induction) from HaoYue merges high‑density pulsed DC current sintering with induction coils to create a more uniform thermal field, reducing center‑edge temperature gradients in larger billets. As advanced sintering equipment, it supports product diameters up to 400 mm, enabling sintering of larger‑sized materials without sacrificing uniformity.

Advantages over SPS System

| Category | Technical Specifications |

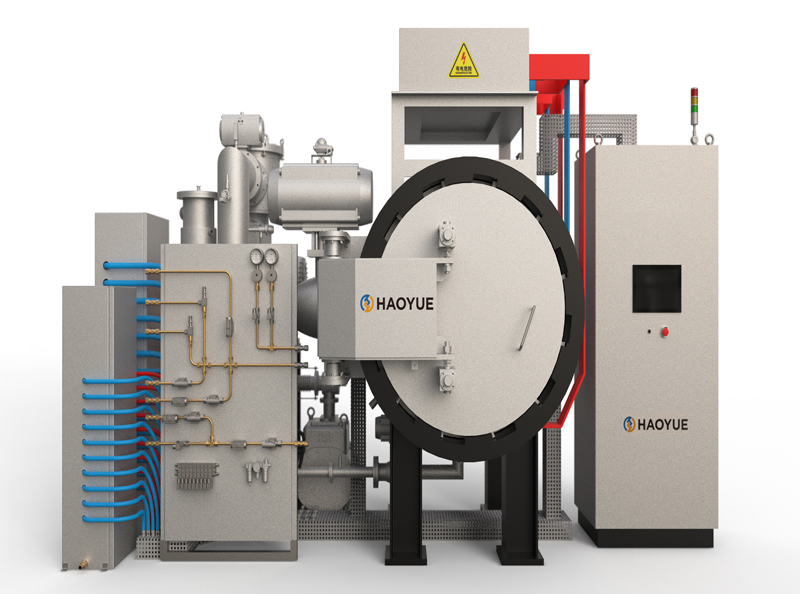

| Combined SPS and Induction Heating | • Utilizes Field Assisted Sintering Technology (FAST)with induction heating. |

| • Achieves 200°C/min heating rate for rapid sintering. | |

| • Ensures homogeneous temperature distribution (up to 200 mm diameter samples). | |

| Sintering Equipment Automation & Control | • HMI+PLC+PID integrated control system for automated temperature, pressure, and current regulation. |

| • Servo-driven axial pressure (±3% precision). | |

| • Safety protocols for vacuum integrity and emergency shutdown. | |

| Data Acquisition & Analysis | • Tracks sintering voltage, current, temperature, pressure, displacement, vacuum degree. |

| • Real-time monitoring and data traceability for process optimization. |

Key Features

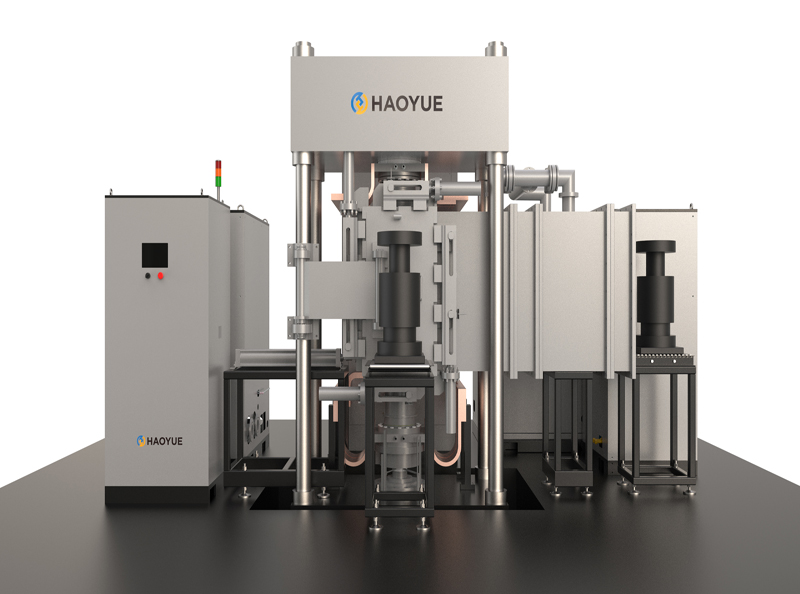

Advanced Heating Mechanism

Pulsed DC Current & Induction Heating: Rapid heating up to 200 °C/min via high‑density current pulses combined with induction coils for enhanced thermal uniformity.

Dual-Temperature Control: Utilizes K‑type thermocouples for low‑temperature ranges and infrared sensors for high‑temperature precision up to 1600 °C.

Pressure Control

Servo‑Driven System: Delivers axial pressure with ±3% precision using bellows sealing to maintain vacuum integrity.

Material Versatility

Wide Composition Range: Processes metals (Fe, Ti, W), ceramics (Al₂O₃, ZrO₂), composites (WC/Co), nanomaterials, and intermetallics for diverse industrial applications.

Safety & Automation

HMI+PLC+PID Control: Automated monitoring of temperature, pressure, and atmosphere, with emergency shutdown upon detecting abnormal conditions.

Hard Alloys SPS Induction Sintering System

Develop WC‑Co alloys using high‑entropy alloy binders for cutting tool applications with uniform microstructures.

Specifications

| NO | Sample diameter (mm) | Pressure (kN) | Pulse Heating Power(kW) | Induction Heating Power (kW) | Hybird Heating Power(KW) | Vacuum(Pa) | Maximum working temperature(℃) |

| S-200D | Φ200 | 2000 | 200 | 200 | 400 | 10 | 2200 |

| S-300D | Φ300 | 3000 | 300 | 300 | 500 | 10 | 2200 |

| S-400D | Φ400 | 4000 | 400 | 400 | 700 | 10 | 2200 |

Application

Energy Storage SPS Induction Sintering System: Manufacture high‑performance electrodes for lithium‑ion batteries and solid‑state electrolytes with uniform microstructures.

Advanced Ceramics SPS Induction Sintering System: Sinter high‑temperature superconductors, piezoelectric ceramics, and thermal barrier coatings with consistent quality.

Biomedical Engineering SPS Induction Sintering System: Produce porous scaffolds for tissue engineering and drug delivery systems with controlled porosity and composition.

Aerospace & Automotive SPS Induction Sintering System: Sinter lightweight TiAl intermetallics and wear‑resistant coatings for critical aerospace and automotive components.

Metals:Fe, Cu, Al, Au, Ag, Ni, Cr, Mo, Sn, Ti, W, Be;

Ceramic oxides:AI2O3, Mulitex ZrO2, Mg, SiO2, TiO2, HfO2;

Carbides :SiC, B4C, TaC, WC, ZrC, VC;

Nitrides:Si3N4, TaN, TiN, AIN, ZrN, VN;

Borides:TiB2, HfB2, LaB6, ZrB2, VB2;

Fluorides : LiF, CaF2, MgF2;

Metal Ceramisc :Si3N4+Ni ,Al2O3+Ni, ZrO2+Ni, Al2O3+Ti, SUS+WC/Co, BN+Fe, WC+Co+Fe;

Metal compounds :TiAl, MoSi2, Si3Zr5, NiAl, NbCo, NbAl, Sm2Co17.

Sintered nanomaterial without significant grain growth

FGM («Functionally Graded Materials»)

Composite materials

Innovative carbide metals

Aluminum and copper alloys as well as intermetallic compounds

Structural and functional ceramics

Main Ingredients

Precautions for Operation & Maintenance

Pre‑Process Checks

Verify vacuum seals, gas purity (argon/nitrogen), and graphite die compatibility to prevent oxidation and arcing.

During Operation

Avoid abrupt pressure changes to prevent sample cracking and monitor infrared sensors for temperature deviations.

Post‑Process Maintenance

Clean residual powder from chambers and electrodes to avoid arcing, and regularly calibrate pressure and temperature systems.

Safety Protocols

Train operators in handling high‑voltage components, emergency shutdown procedures, and proper use of protective gear in high‑temperature and vacuum environments.

Why Choose HaoYue?

As a leading SPS Induction Furnace Supplier, HaoYue leverages over 30 years of expertise in sintering equipment design, ISO and CE/ROHS compliance, and 24/7 technical support to deliver customized SPS Sintering System (SPS+Induction) solutions for both R&D and industrial‑scale production.