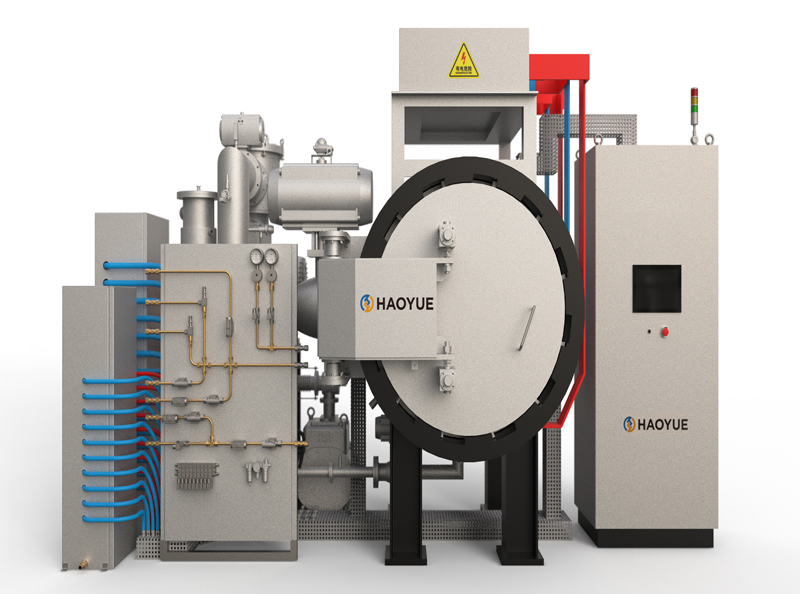

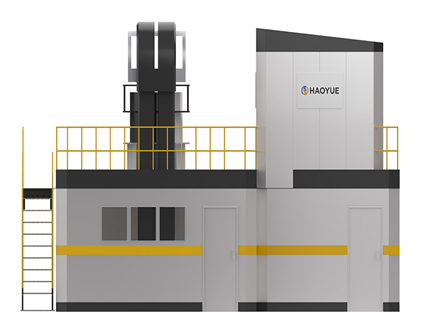

V series Vacuum Furnace (Molybdenum )

This vacuum molybdenum strip furnace is a vacuum resistance furnace that uses molybdenum strips as heating elements, mainly used in ceramics. High temperature sintering and annealing of hard alloys, composite materials, metal materials, etc. in vacuum or protective atmosphere. Fire and brazing

can also be used for high-temperature heat treatment of metal materials under high vacuum conditions or precious metals. Degassing treatment of materials.

Technical Data

Molybdenum Vacuum Furnace excellence is redefined in this vacuum molybdenum strip furnace design from HaoYue, featuring horizontal side‑opening doors for high loading accuracy and easy operation. The vacuum molybdenum strip furnace combines horizontal and side‑opening door structures to ensure precise loading and unloading with minimal operator effort. HaoYue's Molybdenum Vacuum Furnace uses molybdenum heating elements to deliver contamination‑free environments at temperatures up to 2,623 °C, ideal for high‑purity sintering and annealing. By integrating advanced induction coils, the SPS Induction Furnace Supplier capability allows for rapid heating rates of 10 °C/min while maintaining uniformity within ±3 °C across the hot zone.

The HaoYue Molybdenum Vacuum Furnace is engineered for vacuum or inert‑gas processes, utilizing molybdenum wire or strip heaters embedded in high‑purity alumina insulation for optimal thermal stability. Its thermal field has been simulation‑verified to ensure compatibility between heating elements and modular insulation layers, yielding exceptional uniformity and energy efficiency.

Key Components

Furnace Body: Double‑walled 304‑grade stainless steel with water‑cooled panels for rapid quenching and surface protection.

Heating System: Zigzag‑wound molybdenum strip and wire heaters delivering high power density and minimal thermal expansion.

Vacuum System: Combines single‑stage and diffusion pumps to achieve pressures down to 6.67×10⁻⁴ Pa for pristine processing .

Control System: HMI+PLC+PID pressure‑sensing control ensures safe, reliable operation with programmable process curves.

Gas Filling & Cooling: Supports argon/nitrogen backfilling up to 0.04 MPa and offers optional fast‑cooling at 2–10 bar for efficient cycle times.

Features

Fast Heating: Achieves 10 °C/min up to 1,600 °C, reducing cycle times and boosting throughput.

Temperature Uniformity: ±3 °C across a 5‑point measurement zone after a 1‑hour soak at 1,000 °C for consistent material properties.

Multi‑Zone Control: Reserved ports for additional thermocouples allow precise monitoring in each temperature zone.

Safety Performance: Integrated HMI+PLC+PID safeguards against over‑pressure and over‑temperature events.

Design Optimization: Thermal simulations guide modular heating‑element layouts, maximizing uniformity and minimizing energy loss.

Specifications

| No. | Chamber Size(mm) | Ultimate Vacuum (Pa) | Operating Temperature(℃) | Applications |

| V6MO13 | W600*H600*D900 | 6.7x10-4 | 1300 | Sintering /Annealing/Brazing/Degassing |

| V7MO13 | W700*H700*D1000 | 6.7x10-4 | 1300 | Sintering /Annealing/Brazing/Degassing |

| V8MO13 | W800*H800*D1200 | 6.7x10-4 | 1300 | Sintering /Annealing/Brazing/Degassing |

| V10MO13 | W1000*H1000*D1400 | 6.7x10-4 | 1300 | Sintering /Annealing/Brazing/Degassing |

Optional 1400 ℃ solution

Application

High vacuum molybdenum strip furnace is mainly used for non-ferrous metals, stainless steel, titanium alloys, high-temperature alloys. Sintering, annealing, vacuum brazing, degassing and other processes for materials such as hard alloys.

Semiconductor & Optoelectronics: Crystal growth (sapphire, SiC), wafer annealing, and contamination‑sensitive coatings.

Advanced Ceramics & Alloys: High‑purity sintering of Al₂O₃, ZrO₂, and intermetallic compounds.

Glass & Metallurgy: Bright annealing of stainless steels and degassing of titanium alloys for aerospace and medical parts.

Energy Storage: Processing of battery cathode and anode materials under controlled atmospheres.

R&D: Extreme‑condition testing of materials in vacuum or inert environments for academic and industrial research.

Main Ingredients

Precautions for Operation & Maintenance

Pre‑Operation: Check vacuum pump oil levels, gas purity, and inspect molybdenum heaters for surface integrity.

During Operation: Avoid rapid temperature ramps above 100 °C/min to prevent thermal shock in molybdenum elements.

Post‑Process: Clean residual powders, calibrate thermocouples monthly, and replace diffusion‑pump oil to maintain vacuum quality.

Safety Protocols: Operators must use PPE and follow emergency shutdown procedures when handling high‑temperature or vacuum conditions.

Why Choose HaoYue?

With 20+ years of expertise and academic partnerships (e.g., Fudan University), HaoYue Vacuum Equipment Co., Ltd. delivers ISO‑certified vacuum molybdenum strip furnace solutions backed by 24/7 technical support and a 12‑month warranty. Trust HaoYue as your SPS Induction Furnace Supplier and elevate your Molybdenum Vacuum Furnace capabilities.