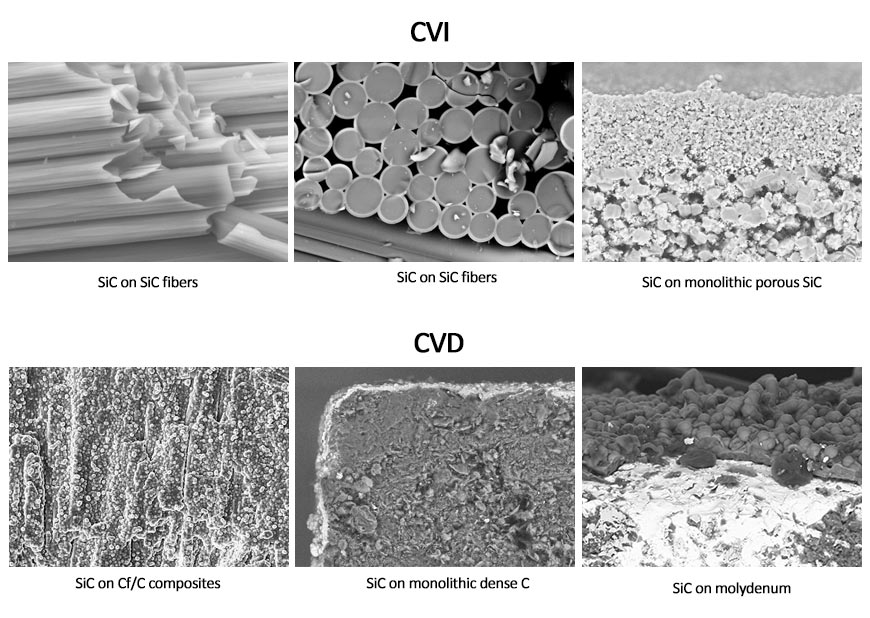

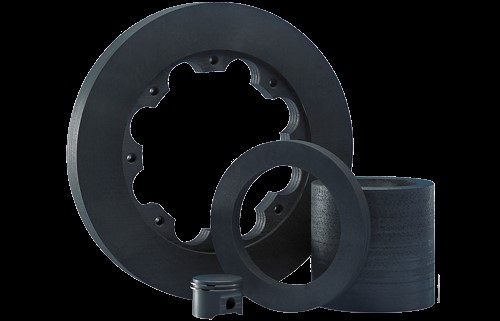

Chemical vapor deposition (CVD) is a process which allows the creation of a deposit on the surface of mechanical parts, to protect them from oxidation and corrosion.

This protective coating is frequently used in aeronautics, especially on the reactors’ turbines blades which run at very high temperatures and in a very oxidizing atmosphere.

This process is usually realized at temperatures around 1000°C and 1150°C under neutral gas like Argon, and consists in creating a sealed enclosure on which mechanical parts are placed.

They are either manually made or in a totally automated way to optimize cycles.

Multiple chemical vapor deposition (CVD) tube-furnace systems are available to synthesize various 2D materials and heterostructures on substrates by chemical vapor transport, some incorporating plasma sources and rapid heating/cooling via sliding stages. Temperature programmable, with pressure controllable via throttle valves and mass flow controllers regulate gas supply.

The CVD systems are used to synthesize a variety of 2D materials and their heterostructures. Examples of past work include the synthesis of few and/or monolayers of MoS2, MoSe2, WS2, GaSe, PdSe2, etc.

Both vertical and lateral heterostructures of GaSe/MoSe2 or isotopic MoS2 were successfully synthesized using a two-step CVD method.

Designed for both 2” and 1” quartz tubes with the maximum temperature of 1200 °C.

Two slidable PE-CVD tube furnaces employ a 300W RF plasma source.

The gas flow rate ranges from 0-500 sccm and can be controlled by mass flow controllers.

A heating belt reaching up to 350 °C can be added outside the furnace to create another heating zone for the second precursor.

A throttle valve is installed for pressure control from 0-760 Torr.

Lower temperature processing compared to conventional CVD

High heating and cooling rate using a sliding furnace

Two channels of gases including Ar and H2 are connected to each furnace to carry out the transport and reaction process.

Each furnace is equipped with a mechanical pump and reaches a base vacuum of < 5 mTorr.

The sliding furnace provides an automatic sliding mechanism allowing the furnace to slide from one side to the other for achieving the max heating and cooling rates of > 100°C/min for growing metastable 2D materials.

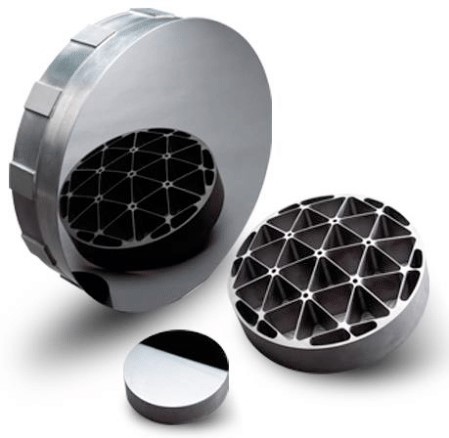

Cold Wall Vacuum furnace design with stainless steel inner and outer jackets with baffled water cooling, designed for easy loading and unloading.

Graphite resistance heated hot zones withstand harsh CVD environments.

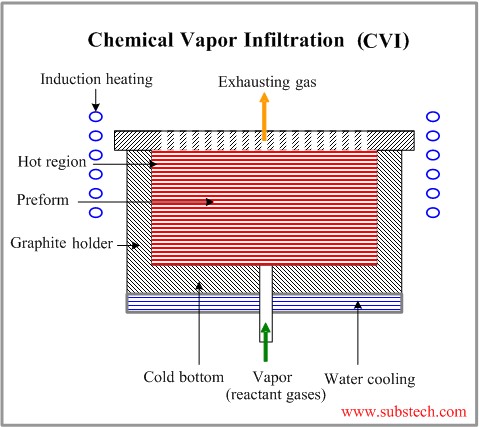

Induction heating available for Carbon CVI applications or ultra-high temperatures.

Vertical top and bottom loading furnaces available as well as horizontal rectangular configurations depending on workpiece size, shape, and quantity.

Operation to 2000°C utilizing state of the art induction heating power supplies. Resistance heated systems for lower temperatures.

Vacuum pumping systems include mechanical pumps/blowers, and optional liquid ring or dry pumping systems operating in conjunction with feedback loop controlled throttling valves providing constant pressure over a wide capacity range. Particulate filters protect against abrasion.

PLC with Industrial Programmable Controller or PC system using software customized for vacuum furnaces, with extensive data acquisition, and remote operation capabilities.

Inert and process gas systems utilizing electronic mass flow control provide accuracy, reproducibility, and flexibility for critical CVD applications. Multiple injection nozzle locations allow for adjusting flow patterns depending on the workload.

Optical Pyrometers available to minimize thermocouple exposure. Corrosion resistant heated manometers provide absolute pressure sensing, independent of gas composition.

Highest Product Consistency is assured by the close temperature gradients and automatic temperature control of each step in the process.

Lowest Cost Operation is provided by the rapid heatup step, unattended operation, fast cooldowns.

Flexibility is provided by the programmable controls which allow different materials and part sizes to be successfully processed without time-consuming adjustment of furnace conditions.

Minimum Maintenance Cost is assured by the heavy construction and ease of access to all components of the furnace.