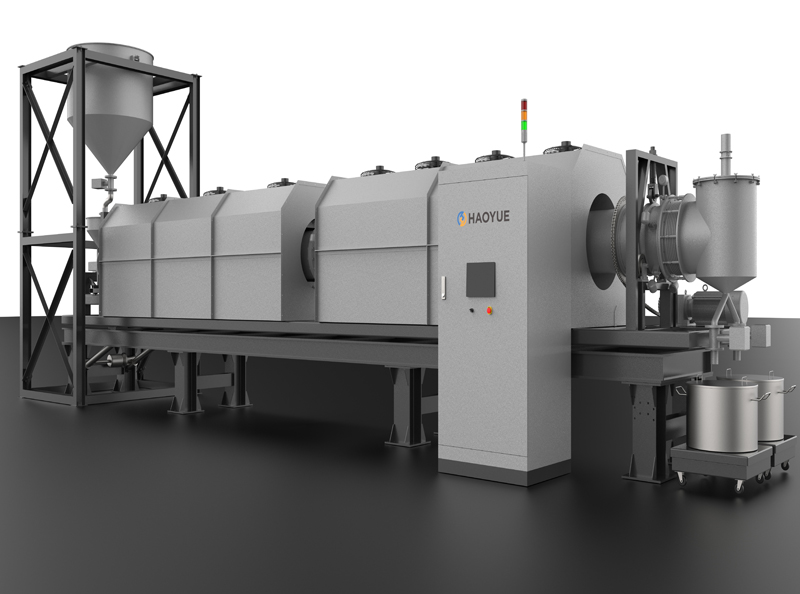

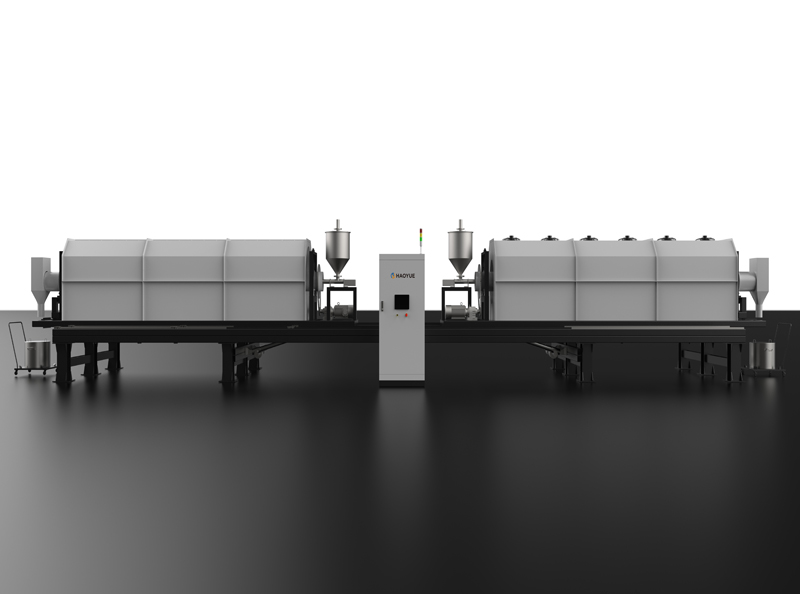

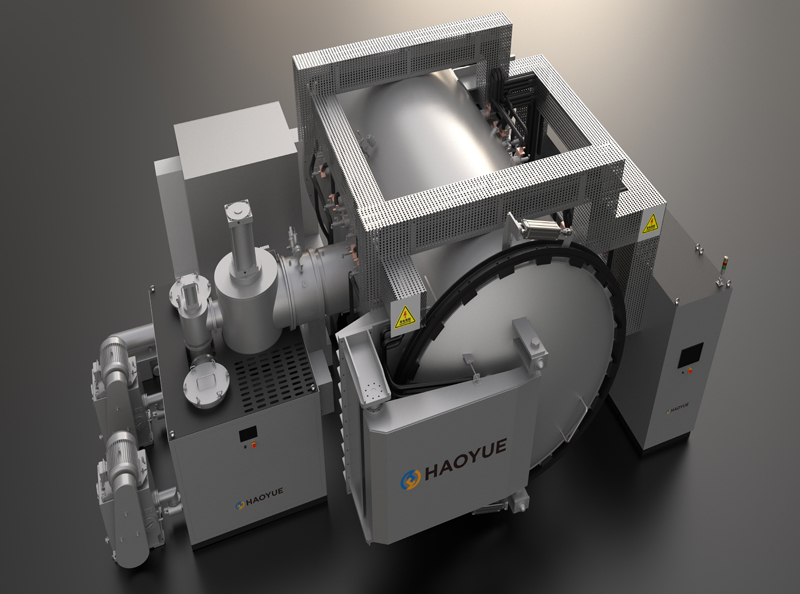

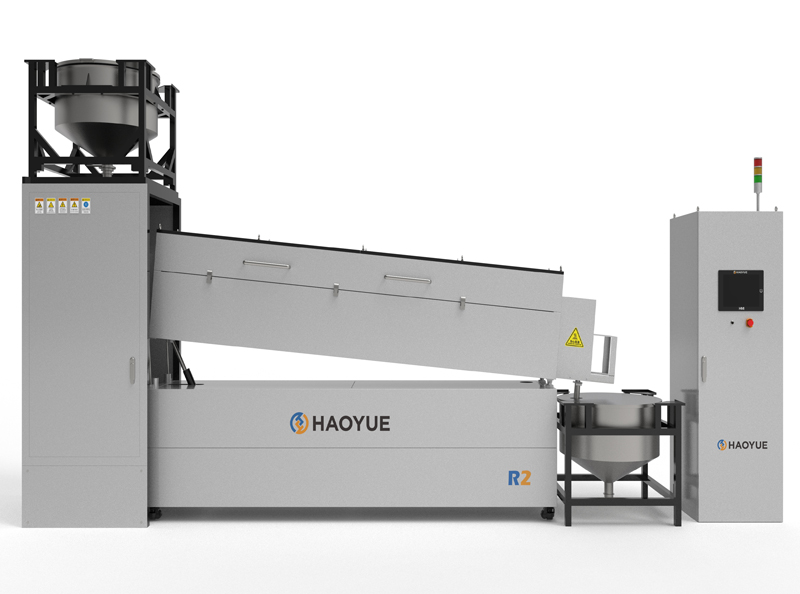

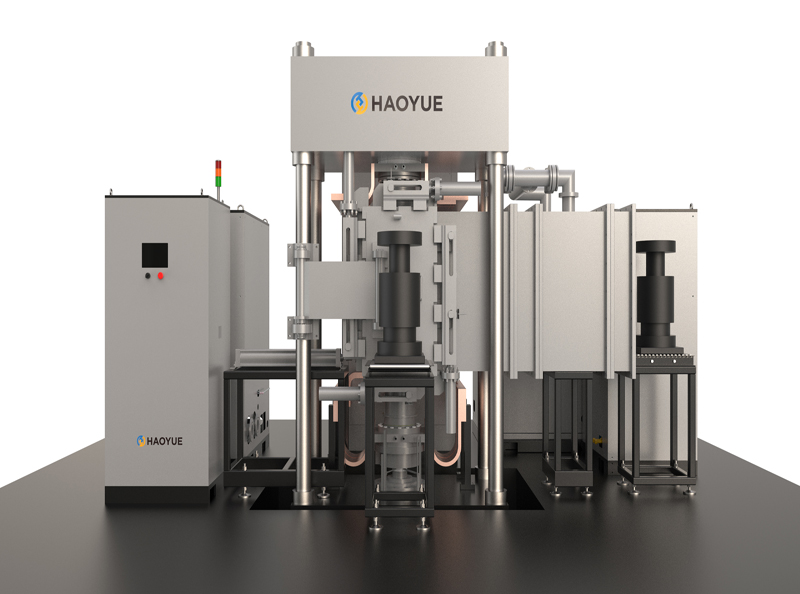

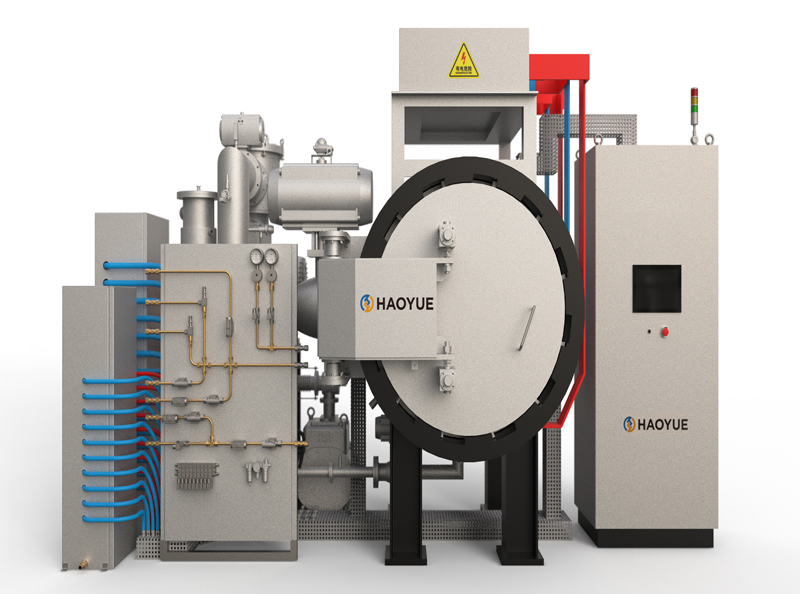

C series CVD\CVI System

High Equipment Stability / Good Temperature Uniformity / Fast Heating Speed / High Control Accuracy / Good Safety Performance

Thermal induced chemical vapor deposition (CVD) is a powerful method for depositing protective coatings on various dielectrics, semiconductors, and metal materials, whether in single crystal, polycrystalline, amorphous, or epitaxial states, in large or small forms. Typical coating materials include pyrolytic carbon, silicon carbide, and boron nitride. By using synthetic precursors, the coating is very pure and meets the typical requirements of the semiconductor industry. Depending on process parameters, there can be multiple layers, ranging from single or several atomic layers to solid protective or functional layers with thicknesses ranging from 10 nanometers to hundreds of micrometers, as well as single chip components with thicknesses up to 100 micrometers, and even up to several millimeters.

Thermal induced chemical vapor infiltration (CVI) is a technique related to CVD, which involves infiltrating porous or fiber preforms into a matrix material to prepare components made of composite materials with improved mechanical properties, corrosion resistance, heat resistance to impact, and low residual stress.

Technical Data

Adopting a vertical, bottom/top door opening structure: high loading and unloading accuracy, easy operation;

Adopting advanced control technology, it can precisely control the flow and pressure of MTS, stabilize the sedimentation air flow in the furnace, and have a small range of pressure fluctuations;

Good temperature uniformity: the average temperature uniformity is ±5°C; Adopting a multi-channel sedimentation gas path, the flow field is uniform, there are no dead corners of sedimentation, and the sedimentation effect is good; Fully enclosed sedimentation chamber, with good sealing e˜ect and strong anti pollution ability;

Good safety performance: Adopting HMI+PLC+PID pressure sensing control, safe and reliable;

Effectively treat highly corrosive exhaust gas, flammable and explosive gases, solid dust, and low melting point viscous products generated by sedimentation; Multi stage efficient exhaust gas treatment system, environmentally friendly, capable of efficiently collecting tar and by-products, easy to clean;

Adopting a corrosion-resistant vacuum unit with a long continuous working time and extremely low maintenance rate;

Specifications

| Numbering | Model | Chamber size(mm) | Ultimate Vacuum (Pa) | Operating Temperature (℃) | Applications | |

| C4VGR16 | VVCgr-56/60-1600 | φ560*600 | 1 | 1600 | CVD/CVI | |

| C6VGR16 | VVCgr-84/90-1600 | φ840*900 | 1 | 1600 | CVD/CVI | |

| C8VGR16 | VVCgr-110/120-1600 | φ1100*1200 | 1 | 1600 | CVD/CVI | |

| C10VGR16 | VVCgr-140/200-1600 | φ1400*2000 | 1 | 1600 | CVD/CVI | |

Application

Chemical vapor deposition furnaces (silicon carbide) can be used for surface oxidation resistant coatings and matrix modification of materials using silane as the gas source. Vertical chemical vapor deposition furnace (sedimentary carbon) can be used for materials using hydrocarbon gases (such as C3H8, CH4, etc.) as carbon sources.

Surface or substrate isothermal CVD/CVI treatment. Horizontal chemical vapor deposition furnaces (SiC, BN) can be used for surface coating of materials, matrix modification, composite material preparation, etc..Substrates for epitaxial wafers, high-temperature refractory materials for crystal furnaces, hot bending molds, semiconductor crucibles, ceramic based composite materials, etc.

Tags