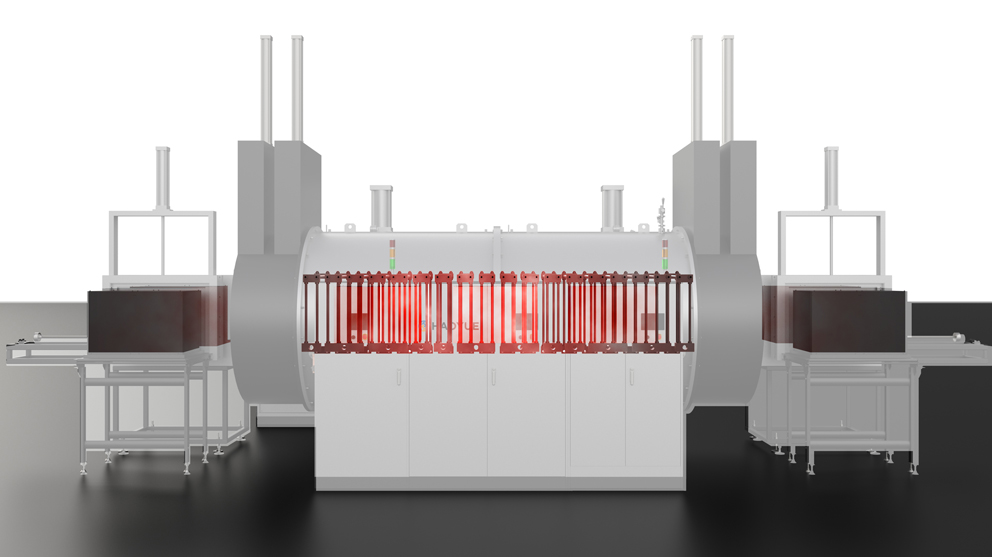

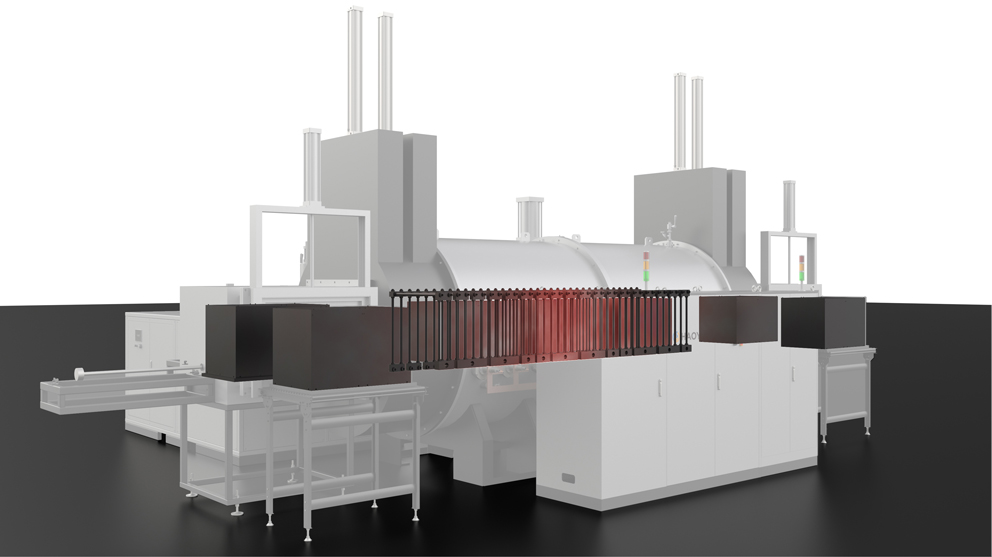

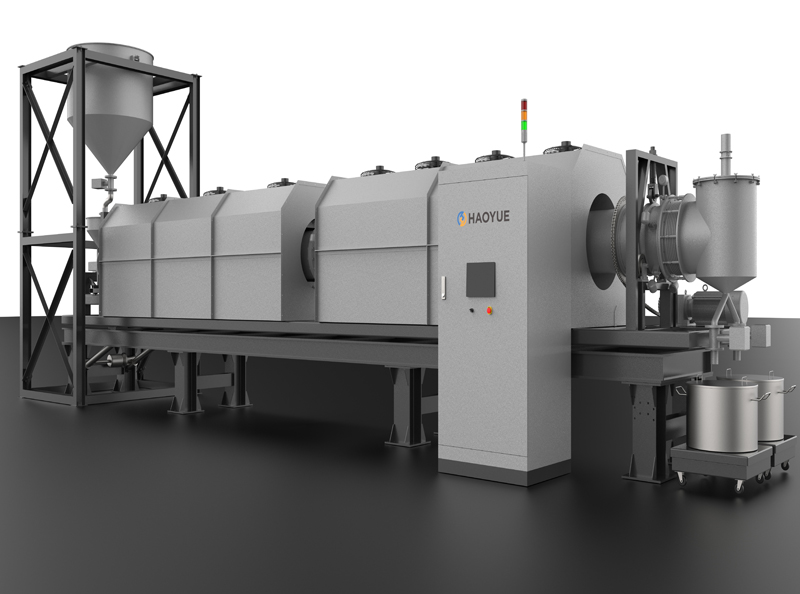

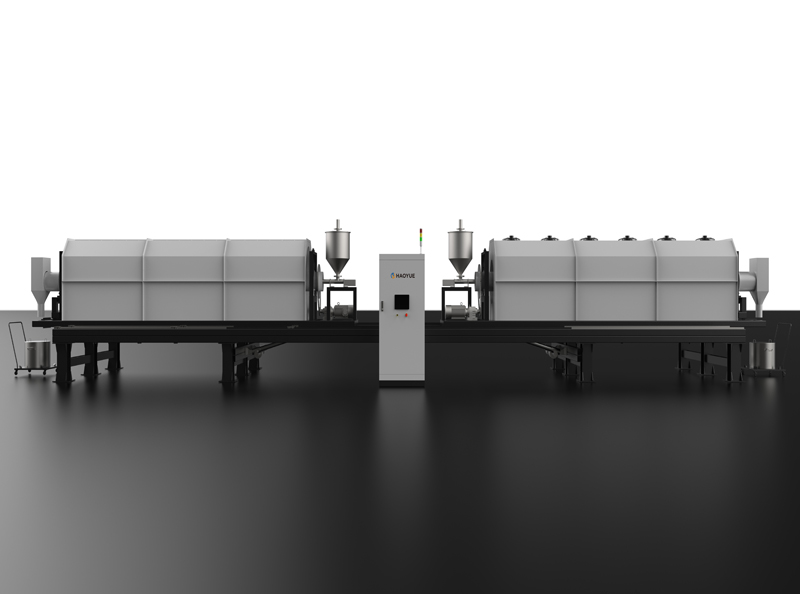

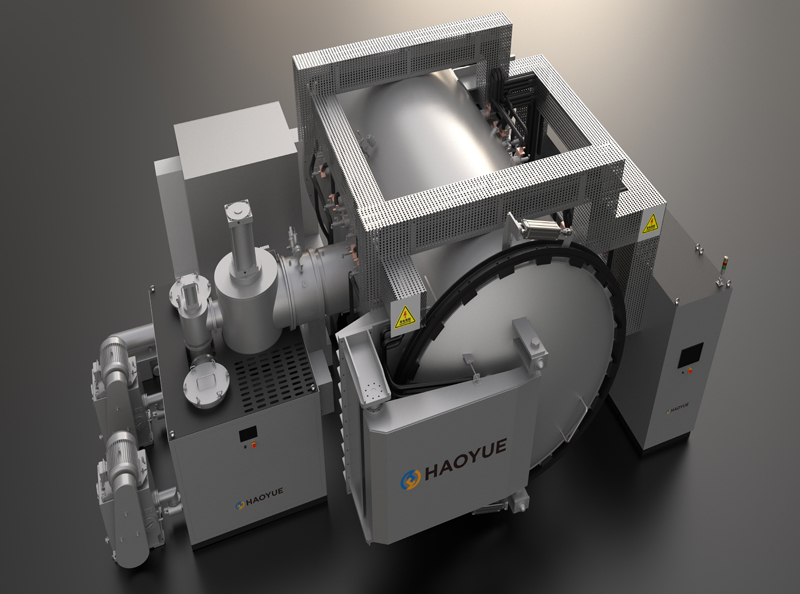

V series Continious Vacuum Furnace

High Production Efficiency / Good Temperature Uniformity / Fast Heating Speed / Good Safety Performance / High Degree Of Automation

This continuous vacuum furnace is a vacuum resistance furnace that uses graphite as a heating element, mainly used in ceramics, hard alloys, A complete set of equipment for high-temperature sintering or annealing of composite materials in vacuum or protective atmosphere can also be used for high-temperature heat treatment of metal materials under high vacuum conditions or degassing treatment of precious metal materials.

Continuous vacuum furnaces have advantages such as advanced technology, high degree of production automation, large processing capacity, and good quality of heat treated products. It can greatly improve the production e˝ciency of enterprises and save labor costs.

Technical Data

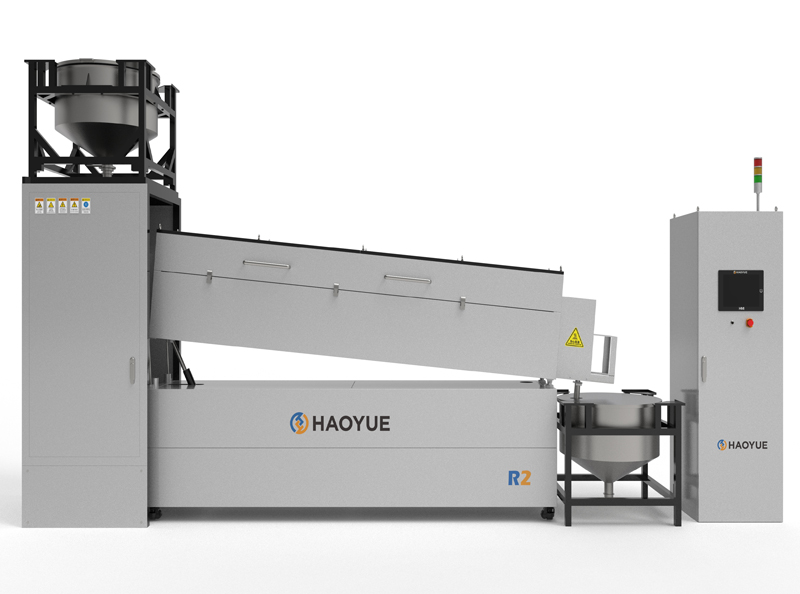

Adopting a multi station design, continuous production can be achieved, resulting in doubled effeciency;

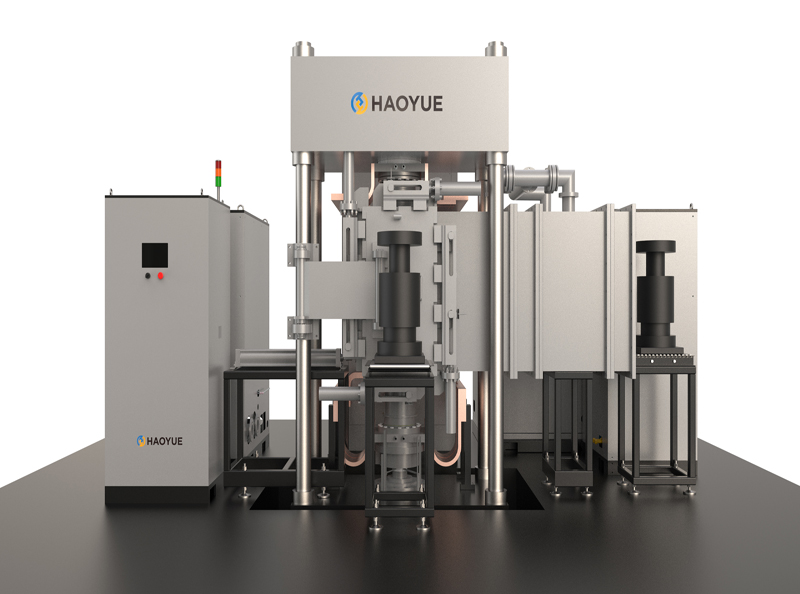

Fast heating: Heating rate of 10°C/minute (˛1600°C), heating rate of 5°C/minute (>1600°C); Good design optimization: The heating chamber's thermal field has been simulated and calculated under thermal conditions, with very high temperature uniformity and compatibility, The heating elements and insulation layer are designed with modular optimization;

Good temperature uniformity: The average temperature uniformity is ± 5°C (5-point temperature measurement, constant temperature zone 1000℃ insulation for 1 hour before detection);

Adopting multi temperature zone control: Reserving multiple temperature measurement holes for high-temperature monitoring purposes;

Good safety performance: Adopting HMI+PLC+PID pressure sensing control, safe and reliable; High degree of automation: If an automatic loading and unloading system is selected, all processes can be fully automated, Digitalization, intelligence, and no need for manual intervention;

Expandable: Sintering, annealing.

Specifications

| No. | Model | Chamber Size (mm) | Ultimate Vacuum (Pa) | Operating Temperature(℃) | Applications |

| V6CGR20 | VCSgr-60/60/90-2000 | 600*600*900 | 1 | 2000 | Sintering /Annealing |

| V8CGR20 | VCSgr-80/80/120-2000 | 800*800*1200 | 1 | 2000 | Sintering /Annealing |

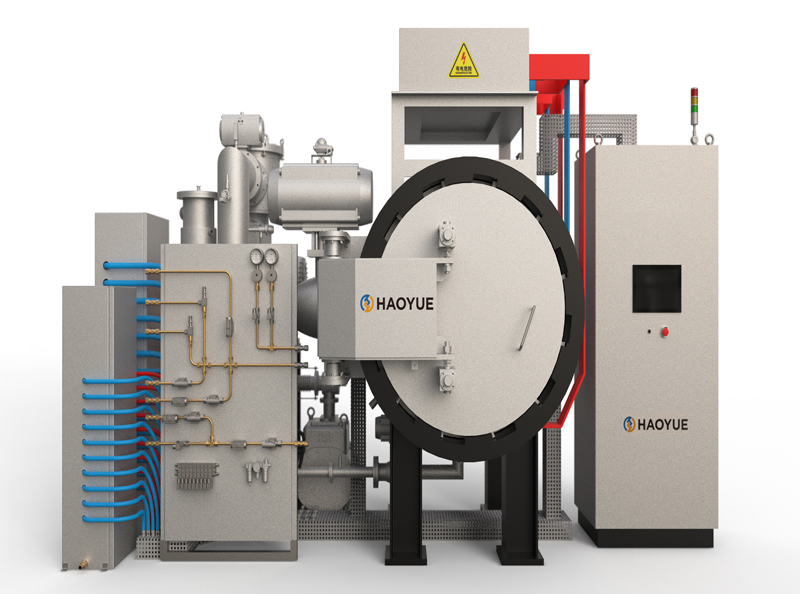

Application

This equipment is a continuous operation type and can be used for graphite electrodes, ceramics, etc. under high temperature and high vacuum conditions, Sintering treatment can also be carried out under the condition of filling a protective atmosphere, or carbon ÿber felt can be subjected to atmosphere treatment, Protection and puriÿcation treatment.

Sintering technology has been widely applied in many industrial industries such as steel, metallurgy, and ceramics, Applications such as hard alloys, ceramics, refractory materials, powder metallurgy, and ultra-high temperature material ÿring are all required, Sintering process. Such as carbon/carbon brake discs, carbon plates, crystal furnace thermal field, hot pressing molds, and high-temperature heating, Body/fastener, thermal field materials, graphite products, carbon paper, carbon cloth, graphene, carbon nanotubes, thermal conductivity, Membrane, etc.