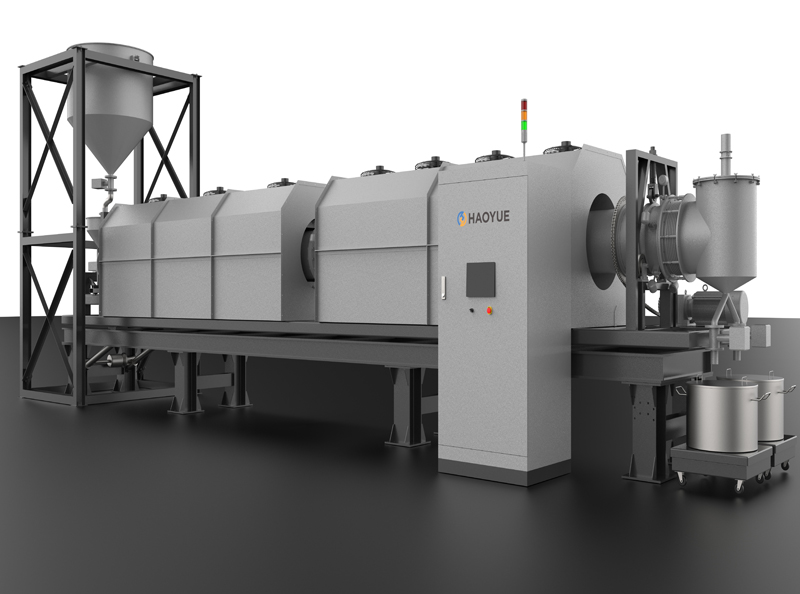

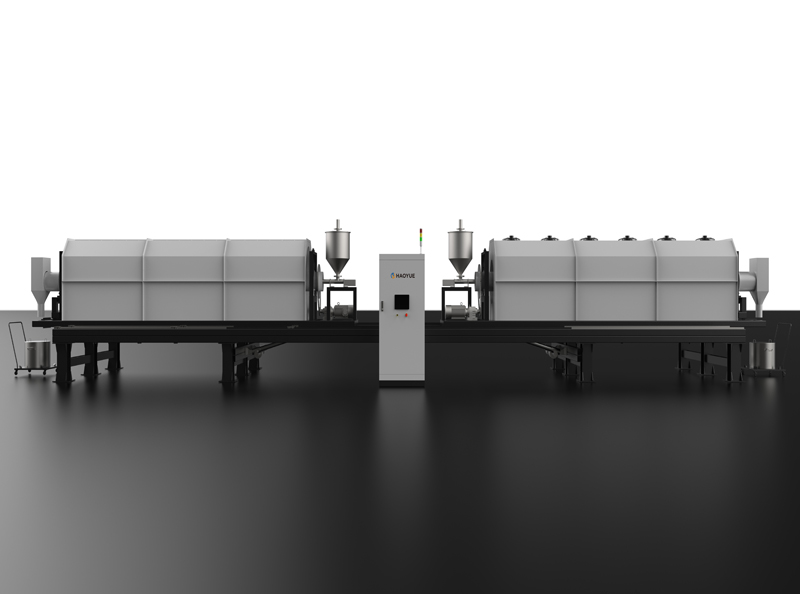

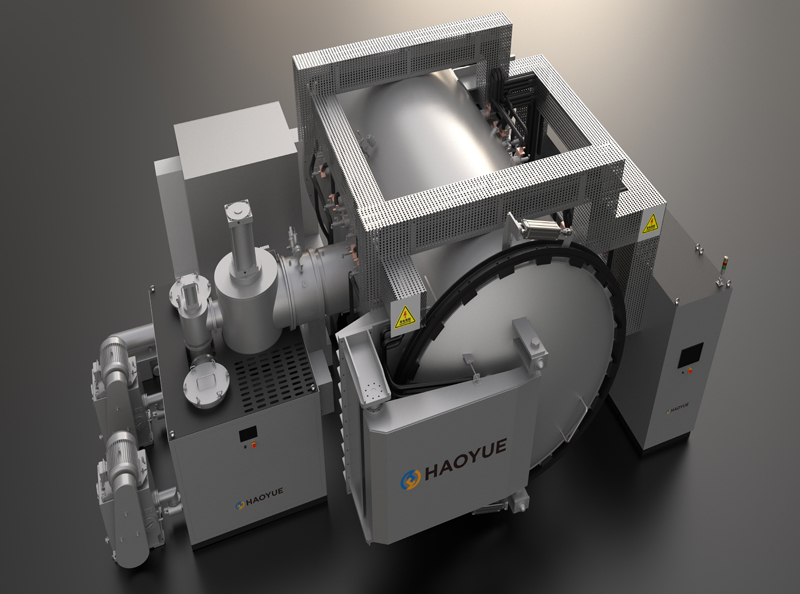

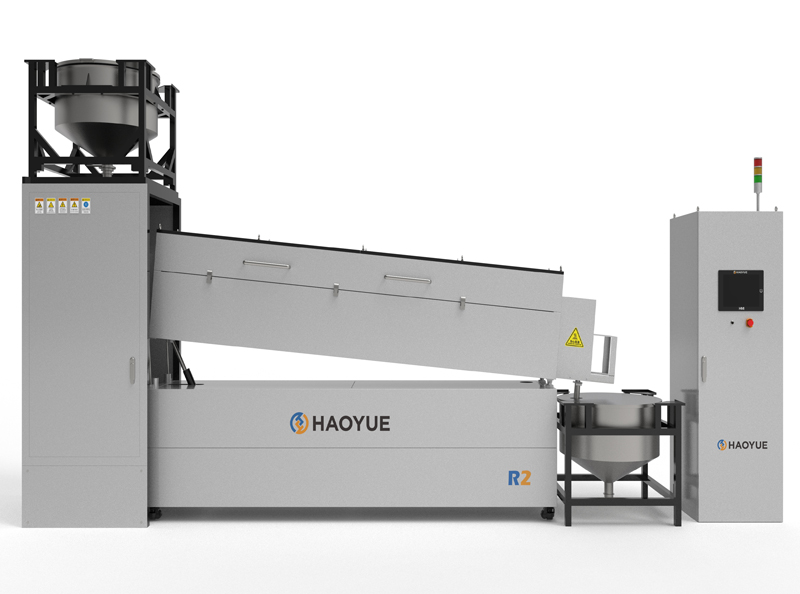

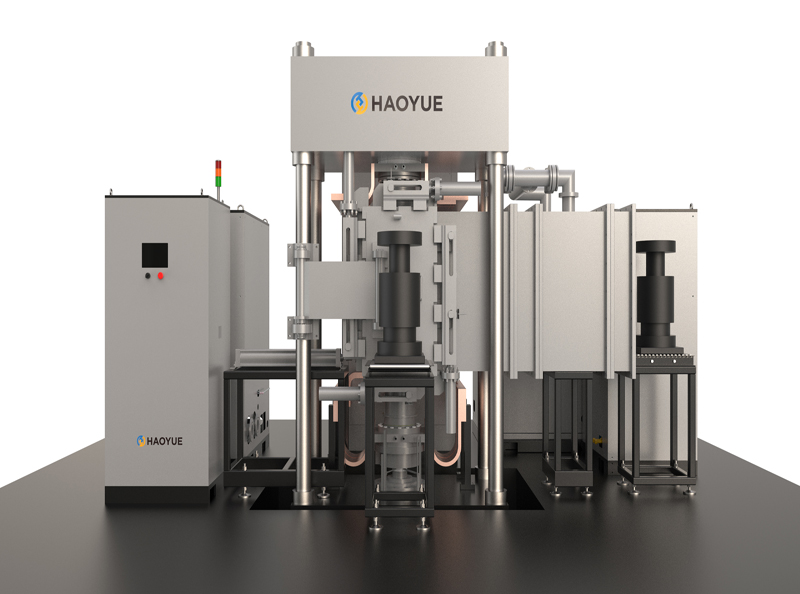

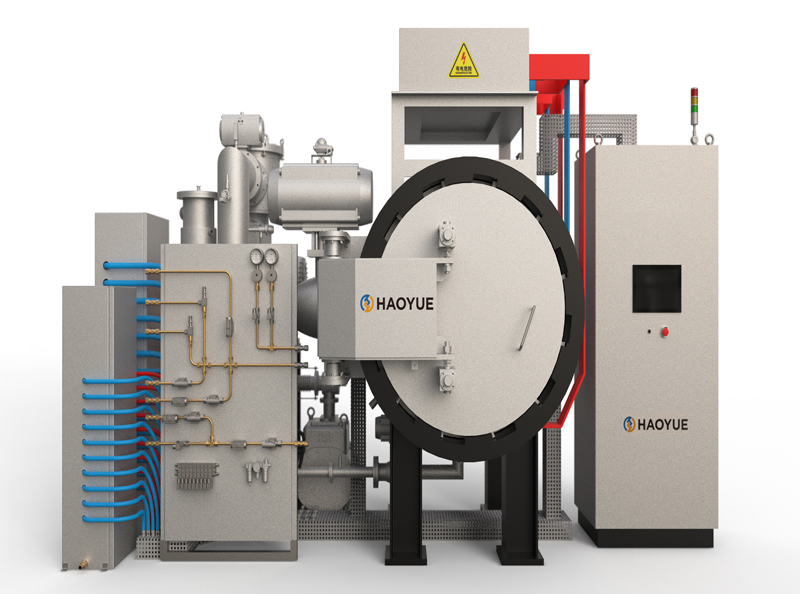

V series Vacuum Furnace

This vacuum furnace is a vacuum resistance furnace that can use graphite/molybdenum strip/tungsten strip/silicon molybdenum rod/molybdenum rod as heating elements. It is mainly used for sintering, annealing, brazing, degreasing, degassing, etc. in vacuum or protective atmosphere for ceramics, hard alloys, composite materials, stainless steel, etc. It can also be used for high-temperature heat treatment of metal materials under high vacuum conditions or degassing treatment of precious metal materials.

Technical Data

Adopting a horizontal and side door opening structure: high precision in loading and unloading molds.

Fast temperature rise and fall: the induction heating rate is 100 ℃ per minute (less than or equal to 1600 ℃), and the resistance rate is 20 ℃ per minute (greater than 1600 ℃);

Good temperature uniformity: The average temperature uniformity is plus or minus 5 ℃ (measured at five points, with a constant temperature zone of 1000 ℃ for one hour before testing);

Adopting single temperature zone control: reserving two temperature measurement holes for high-temperature detection.

Good safety performance: Adopting HMI+PLC+PID pressure sensor control, safe and reliable;

Strong scalability: capable of sintering, brazing, annealing, degreasing, dehydrogenation, degassing, reduction, oxidation, etc

Specifications

| Series | No. | Max.Temperature (℃) | Chamber Size(mm) | External dimensions (mm) | GW (Kg) | Heating Power (kW) | Ultimate Vacuum (Pa) | Application |

| V2 Vacuum Furnace | V2GR20 | 2000 | 200*200*300 | 1425*1550*1850 | 1300 | 45 | 6.7*10-3 | Sintering/Annealing/Degrease |

| V2GR23 | 2300 | 200*200*300 | 1425*1550*1850 | 1300 | 50 | 6.7*10-3 | Braze/Annealing/Degassing | |

| V2MO13 | 1300 | 200*200*300 | 1425*1550*1850 | 1300 | 40 | 6.7*10-3 | Sintering/Annealing/degrease | |

| V2MO16 | 1600 | 200*200*300 | 1425*1550*1850 | 1300 | 45 | 6.7*10-3 | Sintering/Annealing/Degrease | |

| V2W20 | 2000 | 200*200*300 | 1425*1550*1850 | 1300 | 45 | 6.7*10-3 | Sintering/Annealing | |

| V2W23 | 2300 | 200*200*300 | 1425*1550*1850 | 1300 | 50 | 6.7*10-3 | Sintering/Annealing | |

| V2CO20 | 2000 | 200*200 | 1425*1550*1850 | 1500 | 45 | 6.7*10-3 | Sintering/Annealing | |

| V2CO23 | 2300 | 200*200 | 1425*1550*1850 | 1500 | 50 | 6.7*10-3 | Sintering/Annealing | |

| V2MS17 | 1700 | 200*200*300 | 1425*1550*1850 | 1300 | 12 | 6.7*10-2 | Sintering/Annealing/oxidize |

Application

Cemented Carbide(WC、TiC)

Performs dewaxing, degassing, and sintering in sequence

Oxide Ceramics

Performs dewaxing, degassing, and sintering processes in sequence

Application: Aluminium Oxide(Al2O3), Zirconium Oxide(ZrO2)

Non-Oxide Ceramics

Performs dewaxing, degassing, and sintering processes in sequence

Application: Silicon Carbide(SiC), Silicon Nitride(Si3N4), Aluminum Nitride (AlN)

Metals and Alloys

Performs dewaxing, degassing, and sintering in sequence

Graphite

Performs degassing and purification in sequence