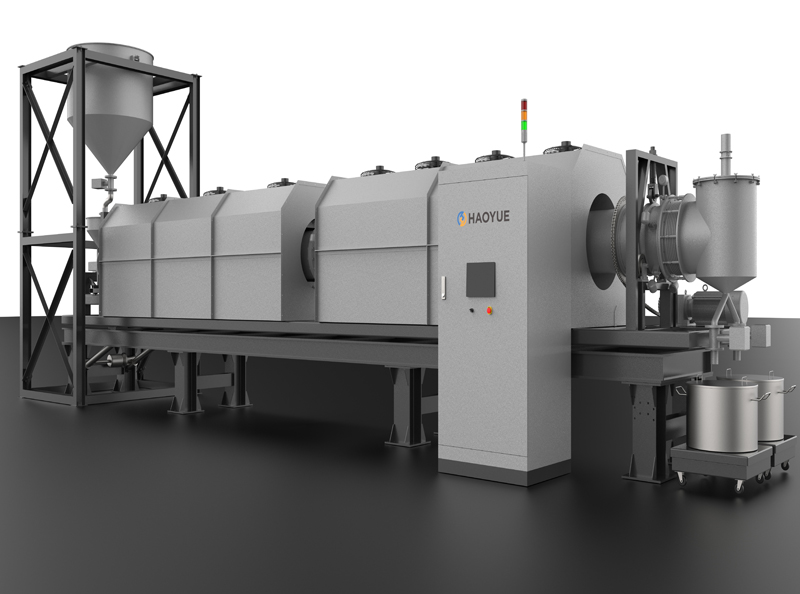

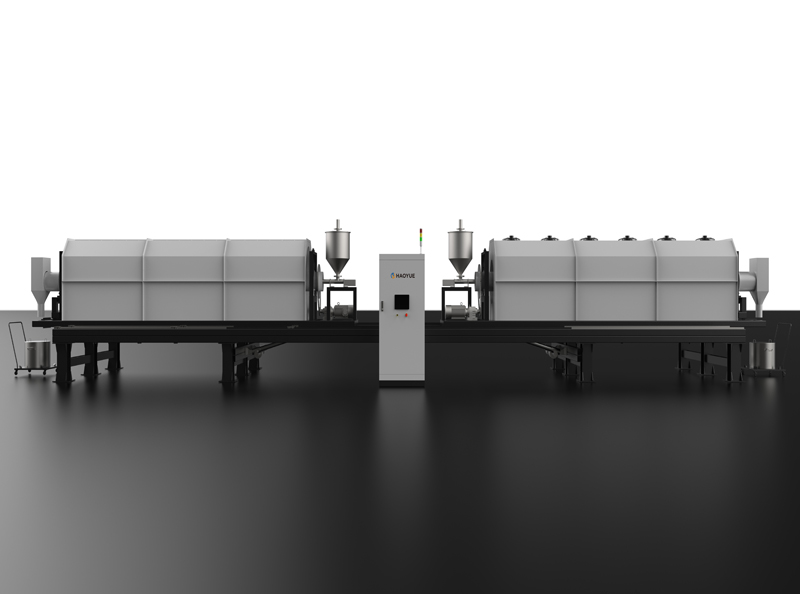

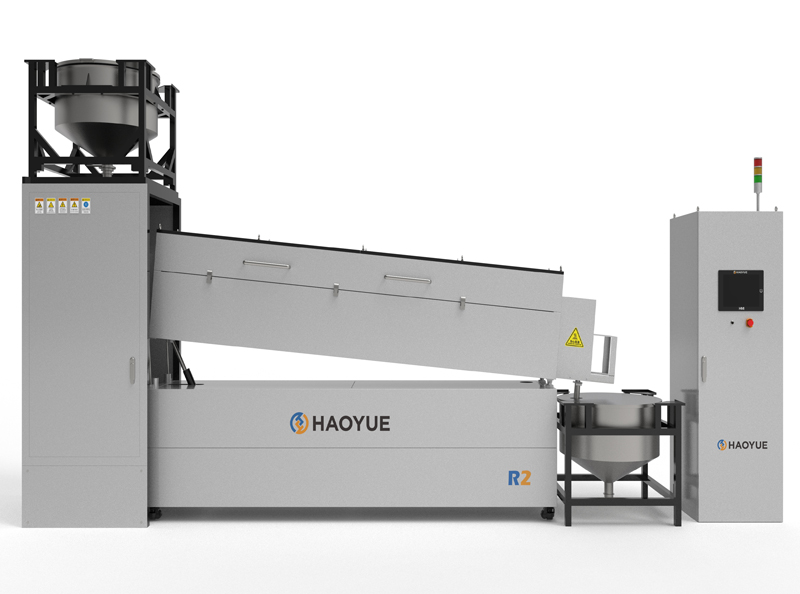

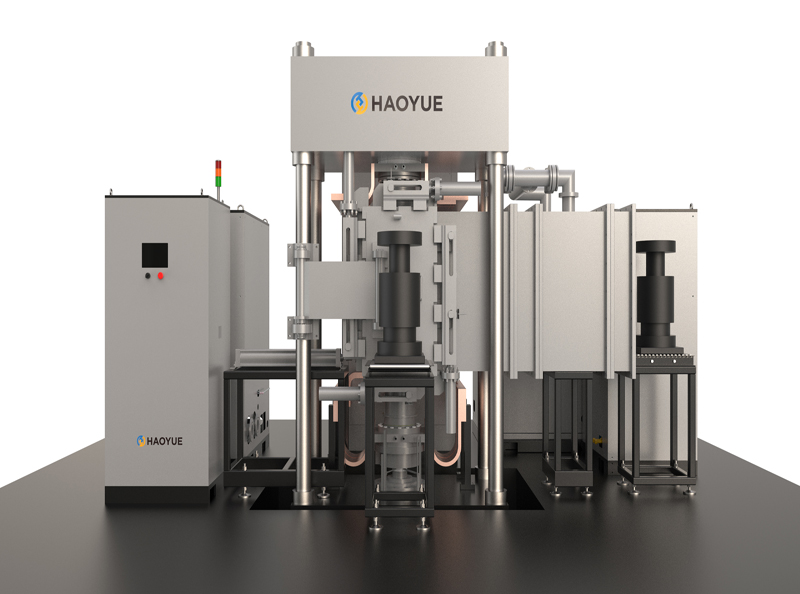

Made In China A2-17 Hydrogen Sintering Furnace

This atmosphere furnace is heated by molybdenum rod,the highest temperature can reach 1700 ℃, specially designed for sintering and heat treatment of materials in inert atmosphere and oxidizing atmosphere, it’s suitable for various heat treatment of special ceramics, electronic ceramics, structural ceramics, functional ceramics, piezoelectric ceramics, magnetic materials, powder metallurgy, rare earth materials, PTC materials, trichromatic phosphors, polishing powders, metals and other materials. The equipment is beautiful in appearance, reasonable in structure and easy to use. It is an ideal product for powder sintering, ceramic sintering, high temperature experiment and quality inspection in universities, scientific research institutes and industrial and mining enterprises.

Technical Data

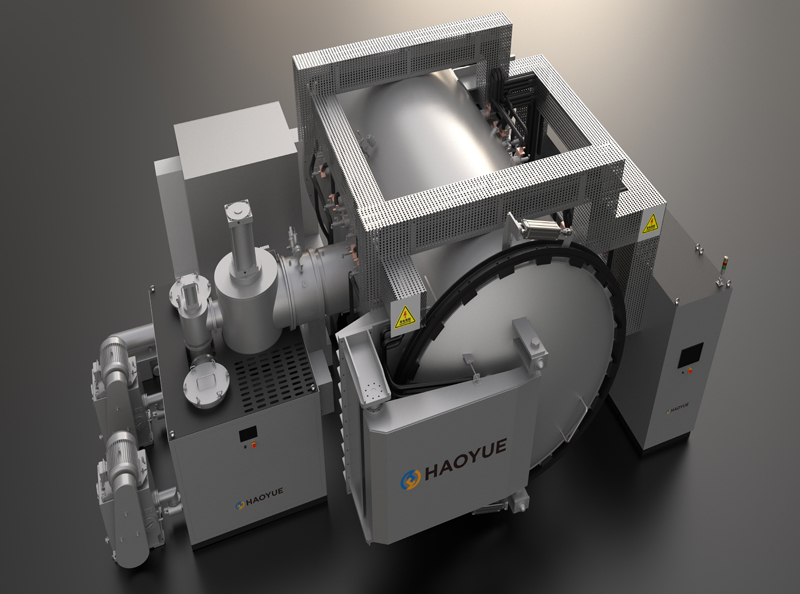

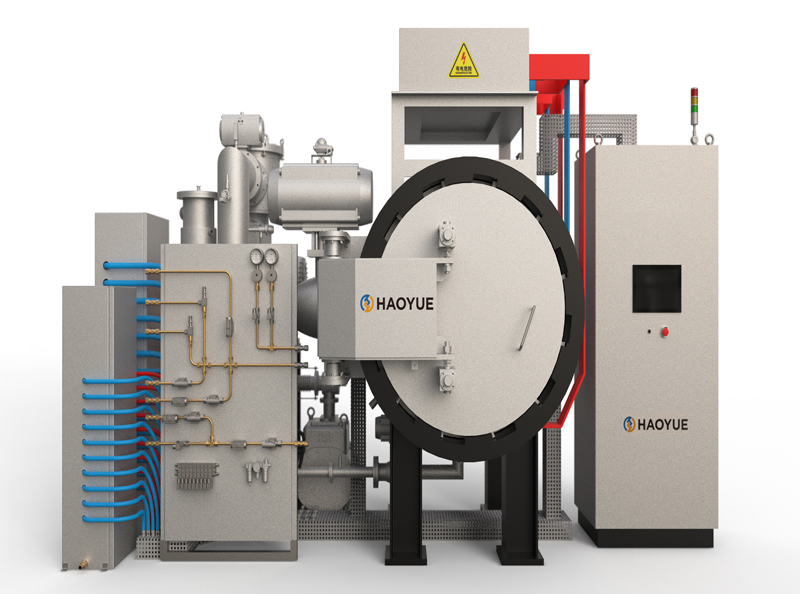

1 The furnace body adopts the circular vacuum tank design, all of which is made of stainless steel and corrosion resistant.

2 The design of the circular vacuum furnace ensures good air tightness of the chamber and has high pressure resistance.

3 Furnace material is made of high-quality poly-crystalline alumina fiber by vacuum adsorption, saving 50% energy and has a uniform temperature field.

4 Multiple safety and explosion-proof measures, a variety of gas emission methods to ensure a good working environment,and can be equipped with automatic ignition device,anti-tempering device and other auxiliary devices to improve the safety of equipment operation.

5 Advanced automatic control and reliable safety interlock: Adopt computer to realize automatic control of temperature and action process, PLC safety interlock. It has sound and light alarm and interlock function such as over-pressure and over-temperature.

Specifications

| A2-17 Hydrogen Sintering Furnace | |

| Model | AHSmo-20/20/30-1700 (A2-17) |

| Max.Power | 9KW |

| Max.Temperature | 1700℃ |

| Working Temperature | 1600℃ |

| Heating Element | Molybdenum Rod |

| Temperature Accuracy | ±1℃ |

| Heat Area Size | 200x00x300mm(WxHxL) |

| Capacity | 12 Liter |

| Max.Working Pressure | ≤0.1MPa |

| Max.Vacuum | 100Pa(1 torr) |

| Thermocouple | W-Re5/26(C-type) |

| Cooling Method | Natural cooling |

| Gases | Hydrogen,Nitrogen,Argon,etc |

| Control Method | Manual / automatic free switch |

Application

Annealing heat treatment of crystal materials

Sintering of thick film materials

MLCC(Multi-layer Ceramic Capacitors)Sintering

Powder synthesis and sintering

Ceramics sintering

High-temperature Test

Quality Test

Heat Treatment of Metals