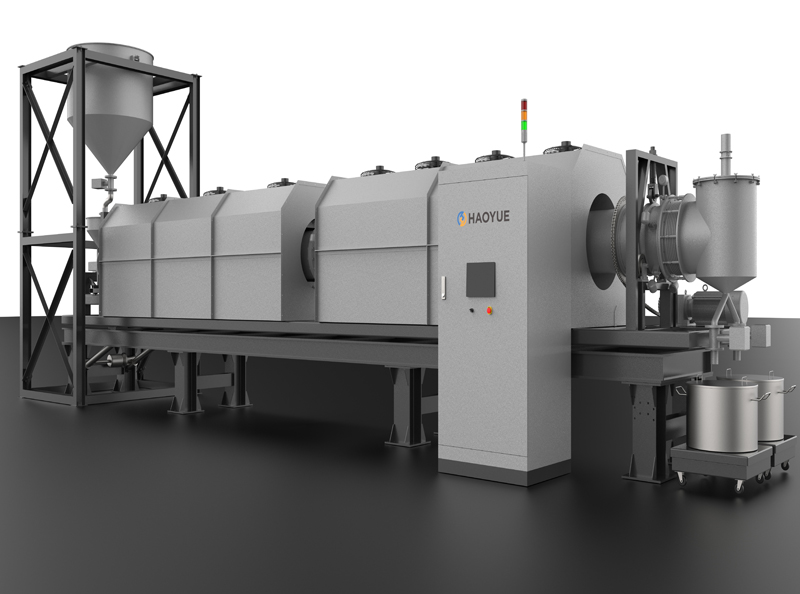

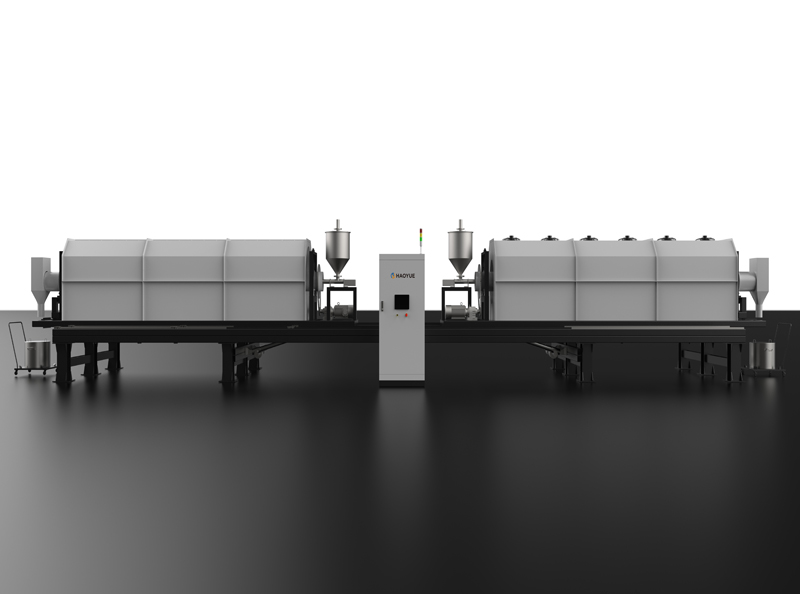

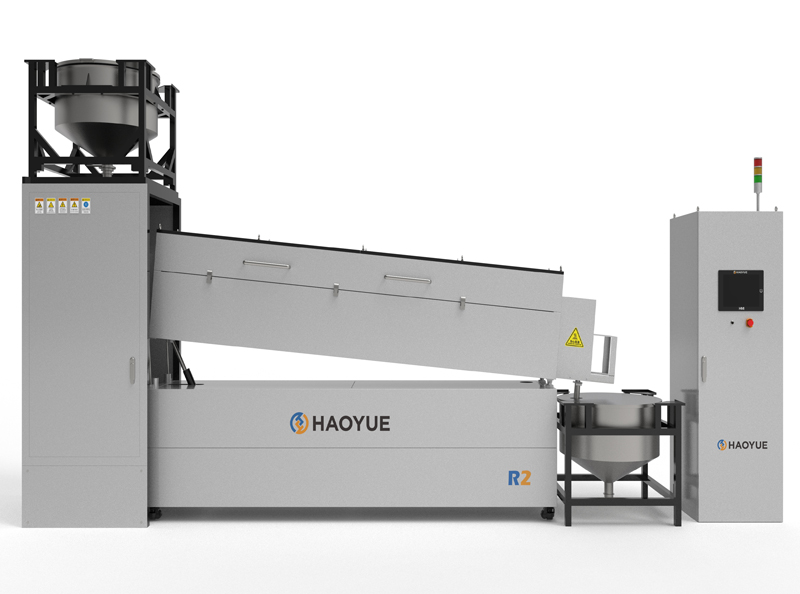

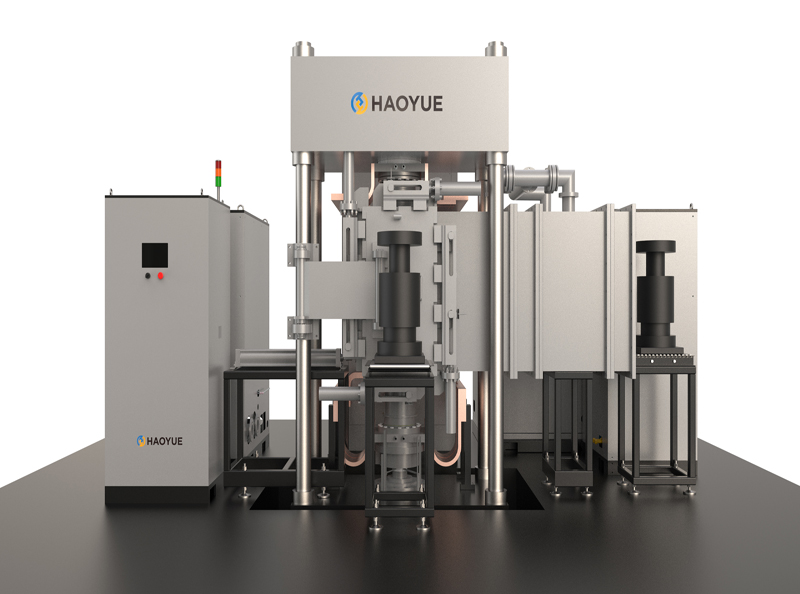

V series Vacuum Furnace (Induction)

Vacuum induction furnace adopts induction heating method and is mainly used in ceramics, hard alloys, and composite materials, Composite materials can be sintered and annealed at high temperatures in vacuum or protective atmosphere, and can also be used for high-temperature heat treatment of metal materials under high vacuum conditions or degassing treatment of precious metal materials. The structural design of this equipment is advanced and reasonable, and the design and manufacturing comply with corresponding national and industry standards and specifications, which can meet the user's usage requirements.

Its supporting products and components have international advanced level and can adapt to long-term, stable, safe, and reliable production needs.

The energy-saving effect of the equipment is good. Convenient and simple to use, operate, and maintain, with beautiful appearance, safe and reliable, and excellent after-sales service

Technical Data

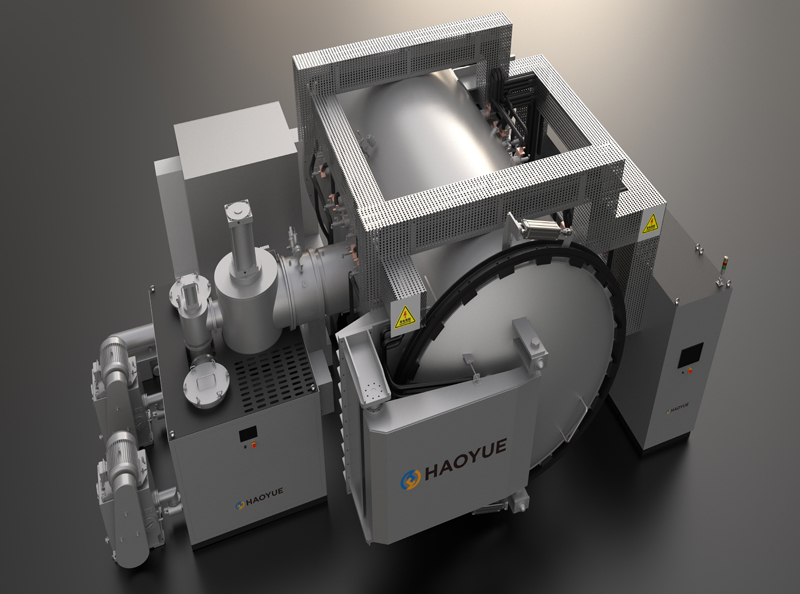

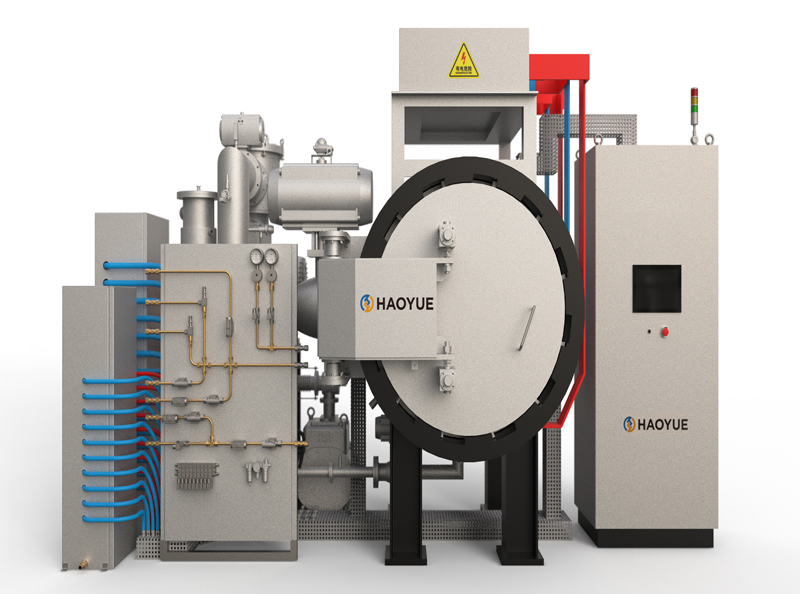

Adopting a horizontal and side opening door structure: high loading and unloading accuracy, easy operation;

Fast heating: heating rate of 40°C/min (˛1600°C), heating rate of 20°C/min

(>1600°C);

Adopting multi temperature zone control: reserving multiple temperature measurement holes for high-temperature monitoring purposes;

Good safety performance: Adopting HMI+PLC+PID pressure sensing control, safe and reliable;

Good design optimization: The induction thermal ÿeld in the heating chamber has been simulated and calculated in thermal state, with very high temperature uniformity and compatibility, The heating elements and insulation layer are designed with modular optimization;

Expandable: capable of sintering, annealing, hydrogen gas, etc..

Specifications

| No. | Model | Chamber Size (mm) | Ultimate Vacuum (Pa) | Operating Temperature(℃) | Applications |

| V8CO23 | VHSco-80/80/120-2300 | 800*800*1200 | 6.7*10-3 | 2300 | Sintering /Annealing/Degreasing |

| V10CO23 | VHSco-100/100/200-2300 | 1000*1000*2000 | 6.7*10-3 | 2300 | Sintering /Annealing/Degreasing |

Application

This electric furnace is a periodic operation type, which can be used for graphite electrodes, ceramics, etc. under high temperature and high vacuum conditions, Sintering treatment can also be carried out under the condition of filling a protective atmosphere, which is widely used in many steel and metallurgical industries, The ceramic industry and other industrial industries have been widely applied, such as hard alloys, ceramics, refractory materials, and powder metallurgy gold, ultra-high temperature material ÿring, and other applications are required.