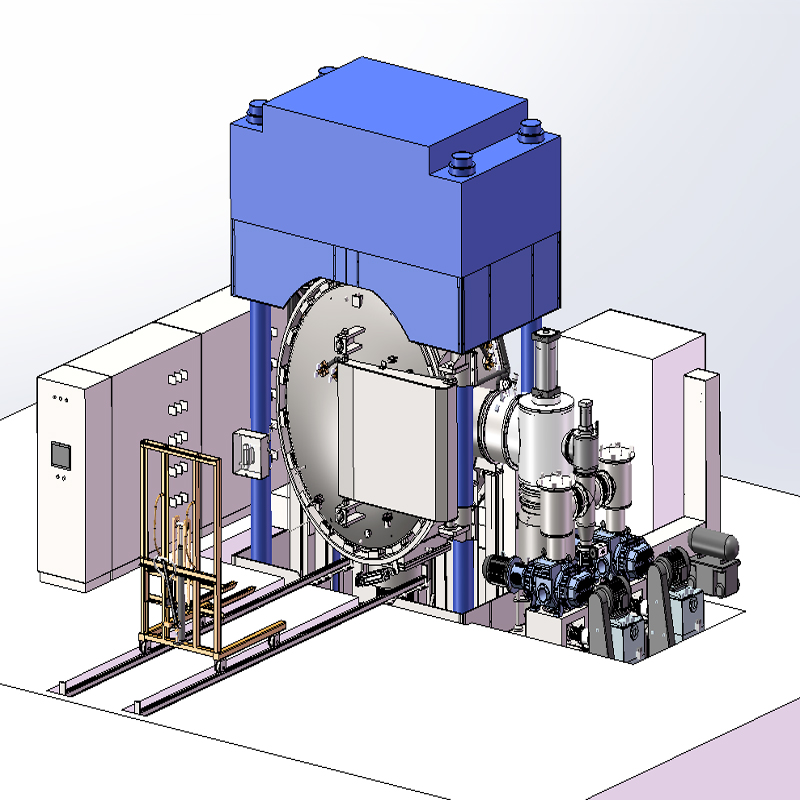

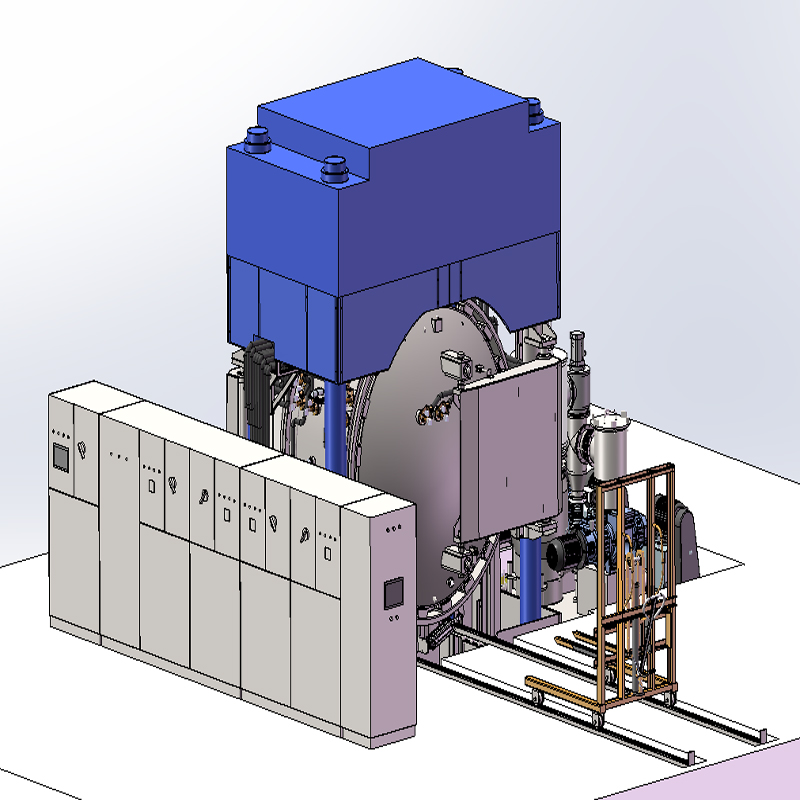

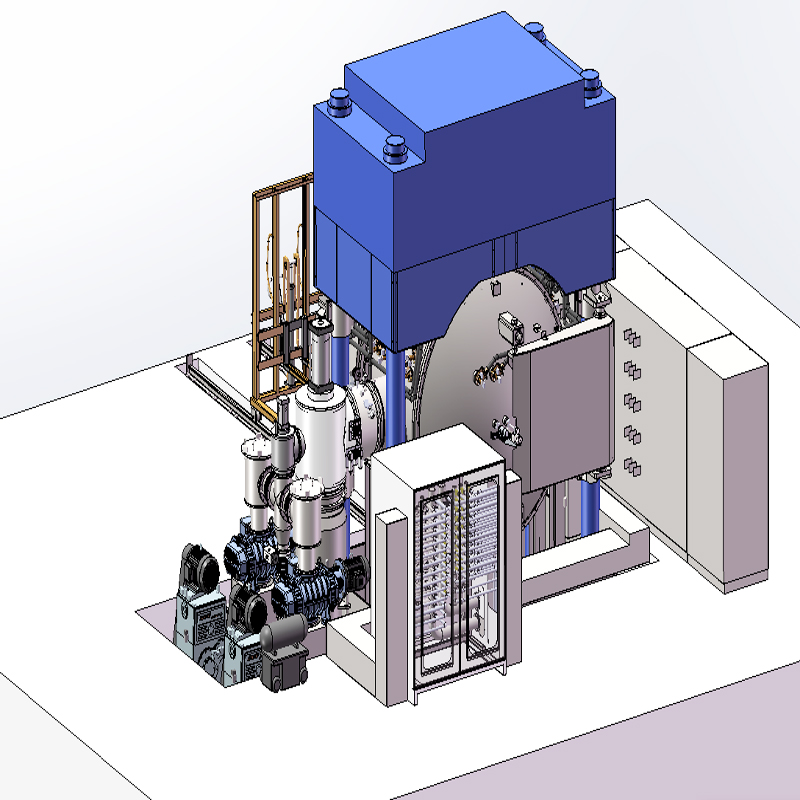

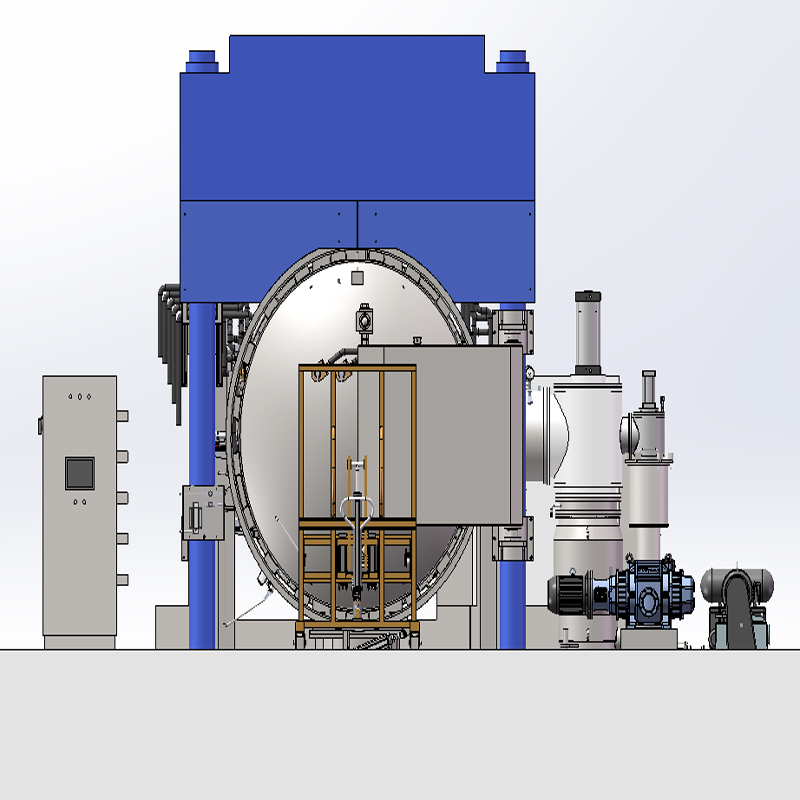

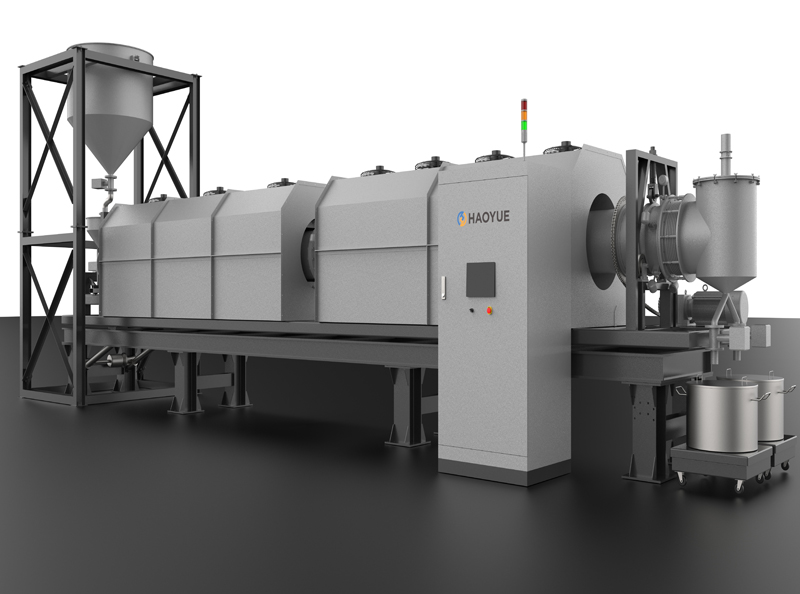

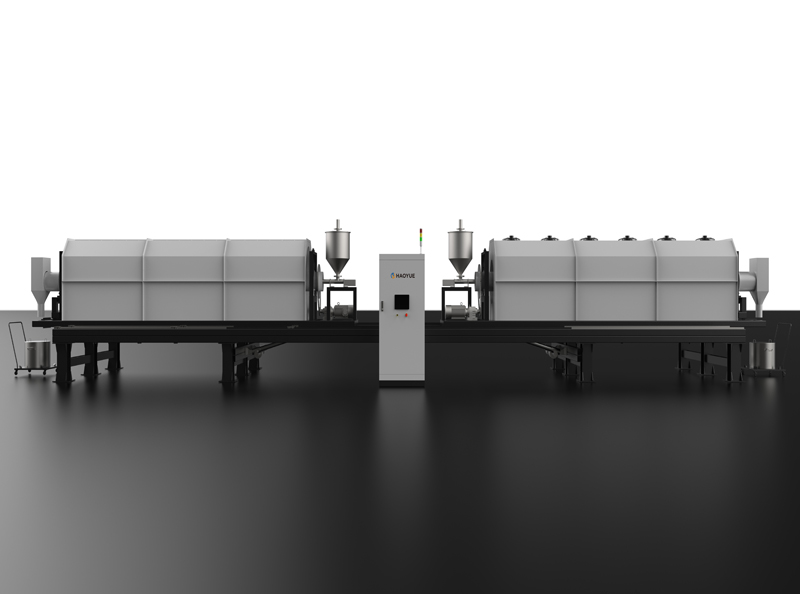

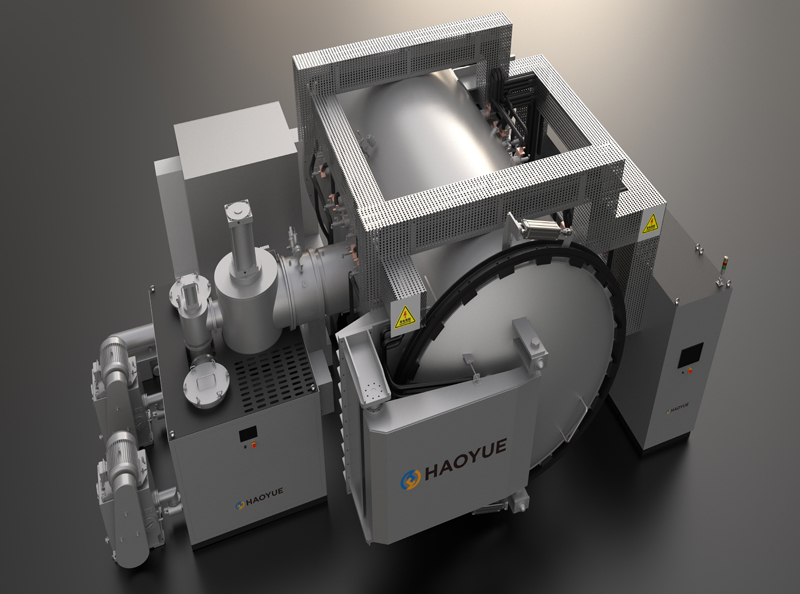

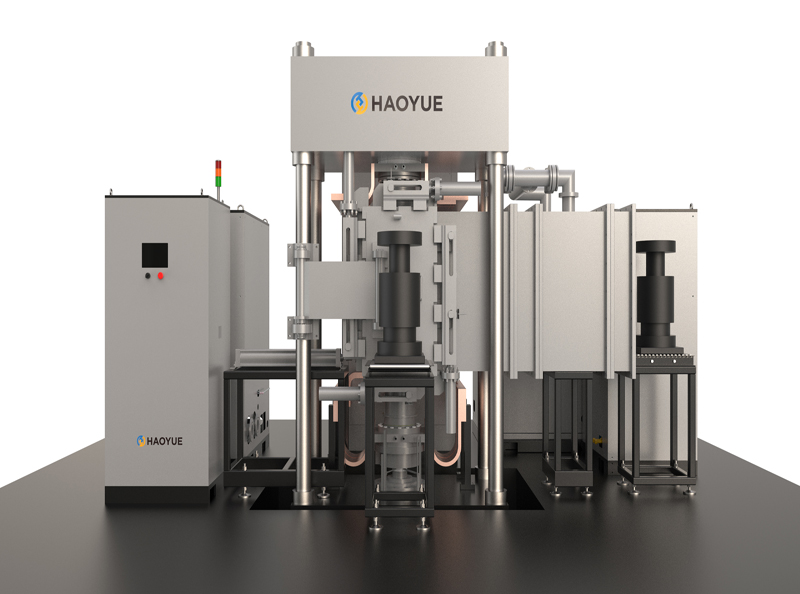

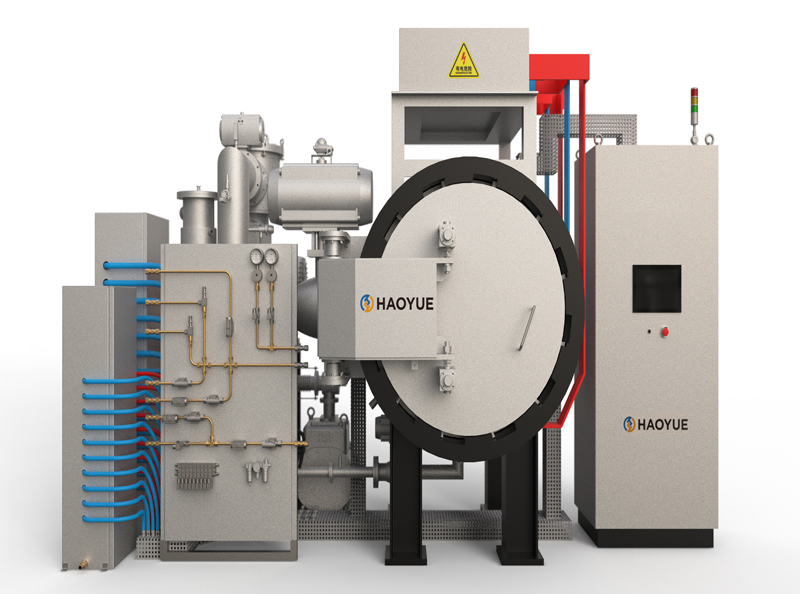

Vacuum Diffusion Bonding Furnace

Vacuum diffusion welding technology is a kind of welding method, which is carried out in vacuum, and the weldments are closely bonded. Under the appropriate temperature and pressure (workpiece bonding pressure), it is maintained for a period of time, so that the atoms between the contact surfaces are diffused, so as to form a connection. Vacuum diffusion technology can be used for welding of dissimilar metals, ceramic / metal dissimilar materials, etc.

Technical Data

1. The thyristor controller optimizes the efficiency of the heating element

2. Simple and safe process operation

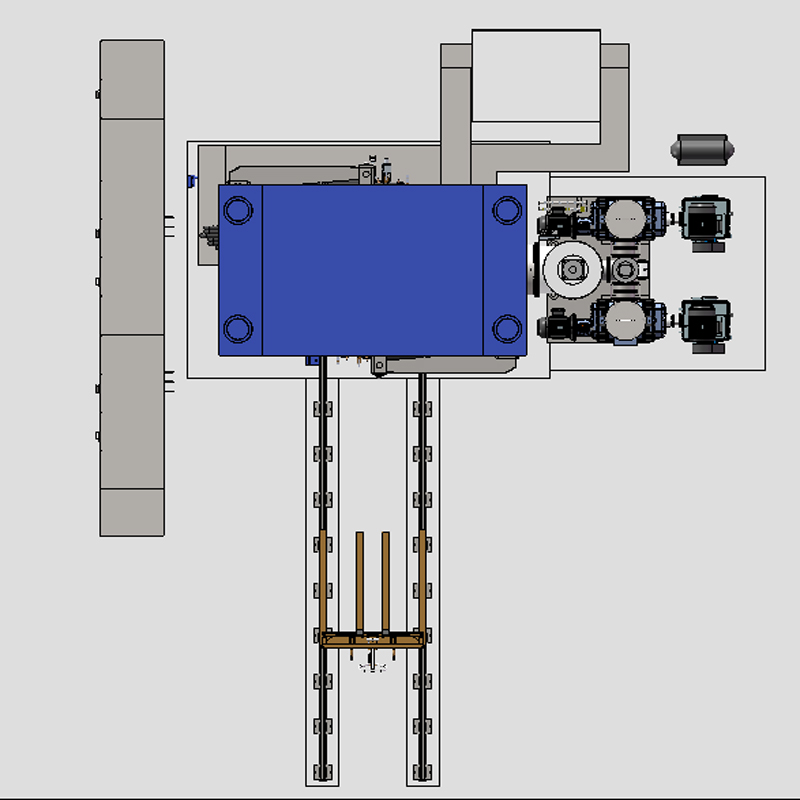

3. Multi compression bar structure design, more uniform pressure distribution

4. Multi pressure sensor design can effectively measure process pressure

Specifications

| model | DB-223 | DB-446 | DB-556 | DB-666 | DB-767 | DB-868 | DB-969 | DB-10610 |

| Effective workspace(mm) | 200×200×300 | 400×400×600 | 500×500×600 | 600×600×600 | 700×600×700 | 800×600×800 | 900×600×900 | 1000×600×1000 |

| Pressure tonnage | 30~300 | 30~300 | 50~500 | 50~500 | 200~1000 | 200~1000 | 200~1000 | 200~1000 |

| Number of indenters | Single / double | Single / double | Single / double | Single / double | Single / double/quadruple | Single / double/quadruple | Single / double/quadruple | Single / double/quadruple |

| maximum temperature | 1300℃ | |||||||

| Temperature uniformity | ≤±5℃ | |||||||

| Ultimate vacuum | ≤6.7x10-4 Pa | |||||||

| Pressure rise rate | ≤0.5Pa/h | |||||||

| Parallelism of upper and lower indenters (mm) | ≤0.1 | |||||||

| Pressure accuracy | ≤±0.5% | |||||||

| Displacement accuracy(mm) | H±0.05 | |||||||

| Air cooling pressure | 2~10bar | |||||||

Application

Vacuum diffusion welding technology is a kind of welding method, which is carried out in vacuum, and the weldments are closely bonded. Under the appropriate temperature and pressure (workpiece bonding pressure), it is maintained for a period of time, so that the atoms between the contact surfaces are diffused, so as to form a connection. Vacuum diffusion technology can be used for welding of dissimilar metals, ceramic / metal dissimilar materials, etc.

Tags