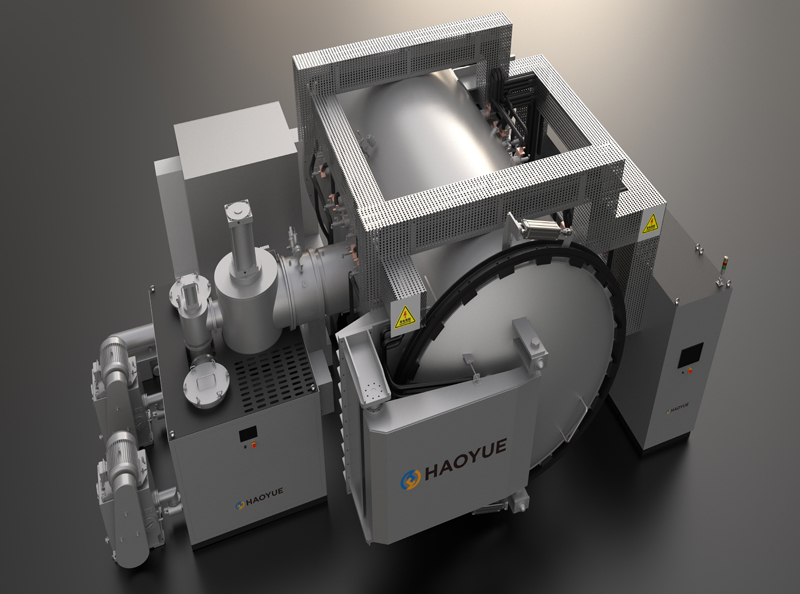

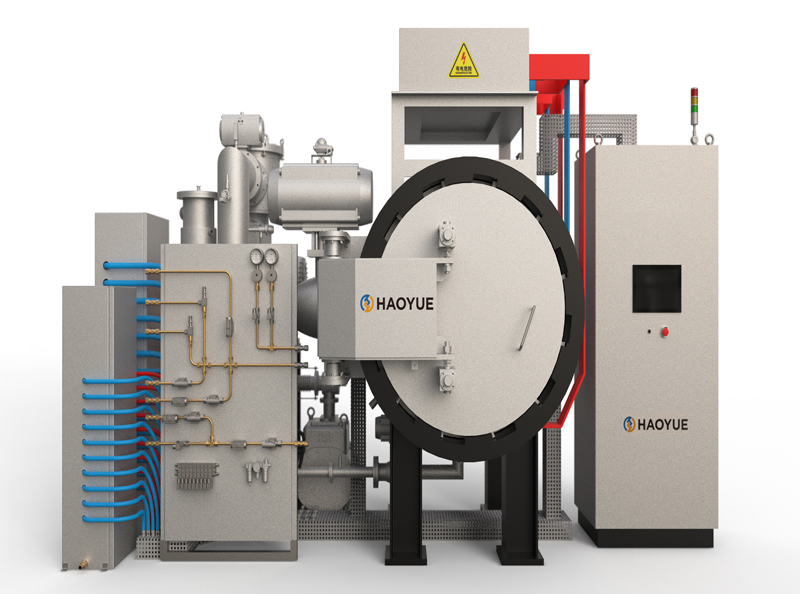

Box type hydrogen furnace(1000 ℃ ~ 1600 ℃)

This 1000 ℃ ~ 1600 ℃ box type hydrogen furnace can be divided into three heating forms: low temperature, medium temperature and high temperature if nitrogen and hydrogen mixture is supplied. The heating elements can be divided into resistance wire (used below 1100 ℃), silicon carbide rod (used below 1400 ℃) and silicon molybdenum rod (used below 1800 ℃). It can pre vacuumize and supply hydrogen, argon, nitrogen and other gases. The furnace is equipped with an inflation overpressure explosion-proof system.

Technical Data

1. The double shell structure is adopted, the inner layer is stainless steel structure, and the shell is carbon steel.

2. The furnace material is made of alumina polycrystalline fiber, which can save 50% energy and even temperature field.

3.The air cooling system is equipped between the double-layer furnace shells, which can make the surface temperature of the furnace body quickly drop, and the surface temperature of the furnace shell is less than 60 ℃.

4. The automatic power-off function of furnace door opening enables automatic power-off after the furnace door is opened.

5. Overtemperature protection function, when the temperature exceeds the allowable setting value, it will automatically cut off power and give an alarm.

6. Leakage protection function, when the furnace body leakage, automatic power off.

7. The temperature control system of box type electric group furnace adopts artificial intelligence regulation technology, which has PID regulation, fuzzy control and self-tuning functions, and can program various temperature rising and falling programs.

8. Program temperature control system can edit 30 segments of program temperature control, optional with touch screen interface control.

9. The RS-485 serial port (purchased separately) can be selected to realize the interconnection with the computer, and the remote control, real-time tracking, historical record, output report and other functions are completed by the special computer control system.

Specifications

| No | Type | Capacity(L) | working zone(mm)W×H×L | Loading method | Note |

| Amini | AHS-10/10/10 | 1 | 100×100×100 | SL | Laboratory |

| A1 | AHS-15/15/15 | 3 | 150×150×150 | SL | Laboratory |

| A2 | AHS-20/20/30 | 12 | 200×200×300 | SL | Laboratory |

| A3 | AHS-25/25/30 | 19 | 250×250×300 | SL | Laboratory |

| A4 | AHS-30/30/40 | 36 | 300×300×400 | SL | Laboratory |

| A5 | AHS-45/45/45 | 91 | 450×450×450 | SL | Industrial |

| A6 | AHS-60/60/60 | 216 | 600×600×600 | SL | Industrial |

Application

This series of resistance furnaces are used for chemical analysis, physical measurement, metal heat treatment and high temperature sintering and annealing in powder metallurgy industry.